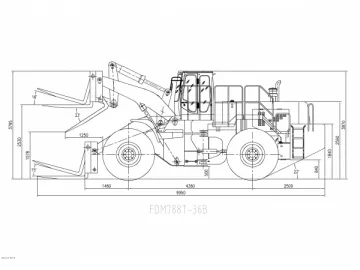

FDM788T-36B Telescopic Handler

The FDM788T-36B telescopic handler is our newly developed engineering machinery. As a popular selection of material handling device for stone lifting and handling, as well as goods stacking and carrying in the occasions such as quarry and harbor, the telescopic handler shows outstanding performance in strong versatility, high mobility and flexibility, strong adaptability to the working environment, etc. The adoption of the telehandler can help reduce the labor intensity of the workers and raise the working efficiency.

Provided with the main functions of both wheel loader and forklift truck, the telescopic handler is furnished with the eight-bar linkage lifting structure coupled with the coaxial flow amplifying steering gear, steering priority hydraulic system with double pumps confluence and shunt, as well as low pressure protection startup and automatic braking device in the case of low pressure and air cutting off. Featuring original appearance, stable loading and unloading operation, as well as high working efficiency and energy saving, the telescopic handler has large load lifting capacity and prominent off-road performance.

Performance Parameter and Dimensions of the 36 Ton Telescopic Handler

| Self weight | 34500kg | Lifting time | 11s | |

| Rated load lifting capacity | 36000 kg | Total cycling time | 22s | |

| Max. lifting load | 38000kg | Hydraulic torque converter | Single stage, four elements | |

| Traveling speed | 0-33km/h | Fuel tank capacity | 240L | |

| Turning angle | 30° | Hydraulic oil tank capacity | 350L | |

| Wheelbase | 4360mm | Engine | Model | HANGFA D10.26T20 |

| Max. grade ability | ≥17° | Rated power | 193KW | |

| Overall dimension (L×W×H) | 9950×3250×3870(mm) | Tires type | 4*29.5-25-44PR | |

Advantages

1. In the case of full load (36t), the telescopic handler can achieve effective lifting height of 3m.

2. The telescopic material handler is equipped with the patented engine manufactured by the Hangzhou Engine Company of China National Heavy Duty Truck Group. Fabricated with the rated power of 175kW, the engine has excellent dynamical characteristic, strong acceleration capability and high reliability. As the superior choice for the heavy equipment, it allows the telescopic handler to work in the dusty environment in virtue of the prominent features of low fuel consumption, high stability and strong power.

3. The outer diameter increase for the pistons of the boom hydraulic cylinder and rotating bucket hydraulic cylinder effectively guarantees the hydraulic system pressure of the stone handling equipment. The strengthened steering hydraulic cylinder can keep the flexible steering in the case of heavy load. The stronger whole hydraulic system pressure ensures enough lifting force.

4. The ultra long wheelbase is conducive to the enhancement of the longitudinal stability of the whole vehicle, keeping balanced working and load, thus actualizing effective lifting for the material. The telescopic handler has more reliable quality and longer service lifetime.

5. The telehandler takes usage of the dedicated strengthened drive axle with larger size by achieving improvement in bearing, gear, wheel hub and supporting shaft. The transmission system works reliably and the supporting weight is enlarged. Due to the use of special brake material for heavy duty truck, the braking effect can be guaranteed effectively. All those delicate designs contribute to the low overall failure rate.

6. The new type cab of the telescopic handler is molded through the high level mould with advanced technology. It is especially supplied to the road roller of the Sanming Heavy Machinery of XGMA. The cab is marked by the strong rigidity, high strength, sound insulation and outstanding impact resistance.

7. The harmonious structure proportion and brand new arc design for appearance make the product look nice, lavish and compact.

8. The boom arm of the telescopic handler is shortened. The fork and fork frame are enlarged by the fork width being up to 250mm. The fork tilting angle can reach 18º. Thus, the problems are solved effectively, which are the material dumping angle and the extraction of the fork in the case of full load and the height of the stacked material getting up to 3000mm. The thickest part of the fork is 110mm in thickness, making the fork have long service lifetime and high durability.

9. Equipped with sophisticated cooling and heating air conditioner, the telescopic handler is more convenient and driver-friendly to operate. The independent transmission oil cooling device plus the handy and comfortable operation is helpful for elevating the system stability.

10. The hydraulic oil tubes for the high pressure part are all the durable and reliable products with the brand of Huaneng.

11. The transmission shaft is produced with larger diameter to enhance the working reliability and durability.

12. Moreover, the telescopic handler makes use of the eight-bar linkage structure with the additional features covering stable loading capability, flexible turning, low center of gravity and strong ability of preventing rollover.

13. Apart from the special design, the structural parts are carefully fabricated with higher level. The thickness of the steel plate for boom arm is 60mm and the hinged plate has a thickness of 60mm also. In addition, the hinge pin and hinged bearing are all strengthened to heighten the bearing capacity comprehensively. As a result, our product is more robust and durable. Its weight is also increased accordingly to 39t.

14. The telescopic handler has the maximum corner radius for the rear counterweight. It won't hit the stone easily. By using the plate with the thickness of 8cm, the rear counterweight weighs 10t.

15. The tires of the product originate from the Shandong Hengyu Technology Group with the model of 4×29.5-25-32PR. Designed even for use in mine, they have high adaptive ability and very long service life expectancy.

16. The telehandler shows the user-friendly design completely in the aspects of special cooling and heating air conditioner (or the warm air blower), wiper spraying settings, etc.

Links:https://globefindpro.com/products/85939.html

-

Bell Annealing Furnace

Bell Annealing Furnace

-

Annealing and Pickling Line (For Stainless Steel)

Annealing and Pickling Line (For Stainless Steel)

-

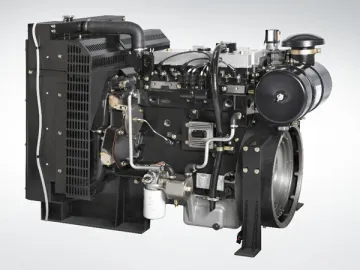

Genset Engine

Genset Engine

-

Continuous Pickling Line(for Strip Steel)

Continuous Pickling Line(for Strip Steel)

-

Welding Machine

Welding Machine

-

Color Coating Line (for Strip Steel)

Color Coating Line (for Strip Steel)

-

FDM8200 Forklift Truck

FDM8200 Forklift Truck

-

Steel Storage Unit

Steel Storage Unit

-

Annealing Furnace

Annealing Furnace

-

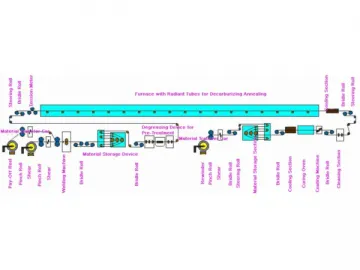

Continuous Annealing Line (For Strip Steel)

Continuous Annealing Line (For Strip Steel)

-

LOVOL® Generator Set Engine

LOVOL® Generator Set Engine

-

Continuous Annealing Line (for Silicon Steel)

Continuous Annealing Line (for Silicon Steel)