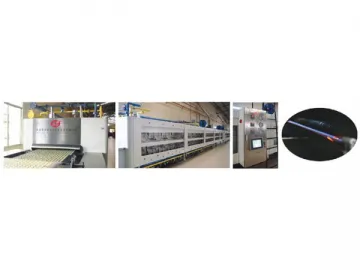

Gas Fired Oven

The gas fired oven directly heats products by firing the natural gas or the LPG, characterized by rapid heating, energy saving and substantially production cost reduction. If the natural gas is adopted, its production cost is lower than that of the heat-transfer oil furnace.

This product adopts the three-section burner and the skewed fire is adjustable. The maximum temperature inside the product reaches up to 380°C, and the baked biscuits are very appealing in color, smell and taste. Besides, this product features low maintenance cost, no pollution, septuple protection system and high safety performance.

Shortcomings of Heat-Transfer Oil Furnace

Compared with the gas fired oven, the heat-transfer oil furnace has lots of shortcomings. Although its heat energy cost for producing per ton of biscuits by using the natural gas is lower than that by using the LPG, the heat-transfer oil furnace has to be mated with a boiler for heating the conduction oil, and thereby the heat conduction oil tube is always in high-temperature and high-pressure state. Also, it has high requirements for metal welding and the oil tube should be replaced every three years for fear of the explosion hazard caused by leakage.

In addition, the biscuits baked by the heat-transfer oil furnace come with slight abnormal taste of conduction oil, which seriously affects the taste of biscuits. With slow heating, long time for temperature regulation, long stand-by time and low furnace temperature, it maximally can reach 260-280°C, thus it is only used for making medium or low-end biscuits.

Constituents

The gas fired oven is mainly comprised of operating system, baking unit, electrical elements and auxiliary mechanisms.

1. Operation System

a. It takes the programmable logic controller (PLC) as the core and comes with a LCD touch screen.

b. The programmed operation design stupendously avoids hazards caused by maloperation.

c. The dynamic monitoring screen shows normal operating condition or malfunction location, facilitating to rapidly solve the problems.

2. Baking Unit

a. The burner is exactly sited above and below the oven band and directly bakes the biscuits via burning the inflammable gas.

b. The inner plate is coated with the organosilicon heat-resistant lacquer which can maximally withstand a high temperature of up to 400°C.

c. Each temperature zone is configured with a three-section burner whose fire can be separately adjusted.

3. Electrical Elements

a. The gas fired oven is designed with an automatic PID temperature control system whose accuracy reaches ±1°C.

b. The nine alarm systems ensure safe production to the largest extent.

4. Auxiliary Mechanisms

a. Each temperature zone is equipped with an individual exhauster to expel the waste gas from the oven.

b. The specially designed adjusting plate is installed onto each oven section for adjusting the exhaust volume of different oven sections.

c. The equipped preheating unit effectively prevents the bonding of biscuits and oven band.

d. The roof of the gas fired oven is designed in anti-explosion and pressure relief structure.

e. The panel of the control cabinet is made of the stainless steel, and looks clean and nice.

General Parameters

1. Total power: 28.8KW

2. Working speed of oven band: 8-22m/min.

3. Gas pressure: 4-5KPa

4. Heat insulating material: Rock wool

5. Volume weight: 80kg/m3

| Model | W1 (mm) | W2 (mm) | Standard length (m) | Liquid gas consumption (kg/h) | Nature gas consumption (m3/h) | Temperature zone quantity | Production capacity (kg/h) |

| HF600 | 2055 | 660 | 39.9 | 20-22 | 30-33 | 3 | 600 |

| HF800 | 2255 | 860 | 39.9 | 28-31 | 42-47 | 3 | 800 |

| HF1000 | 2455 | 1060 | 61.1 | 40-43 | 60-65 | 4 | 1100 |

| HF1200 | 2655 | 1260 | 61.1 | 48-51 | 72-76 | 4 | 1300 |

Related Names

Biscuit Maker | Rice Cracker Maker | Industrial Baking Equipment

Links:https://globefindpro.com/products/86369.html

-

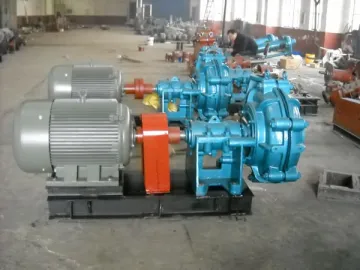

ZMR Series Horizontal Rubber Centrifugal Slurry Pump for Mining

ZMR Series Horizontal Rubber Centrifugal Slurry Pump for Mining

-

ZJ Pump Mechanical Seal

ZJ Pump Mechanical Seal

-

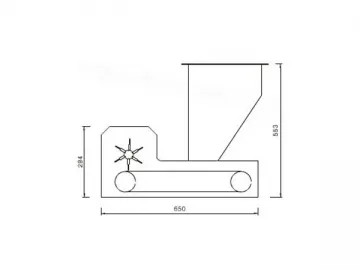

Gauge Rolls

Gauge Rolls

-

ZD Series Single Volute Slurry Pump for Metallurgical Industry

ZD Series Single Volute Slurry Pump for Metallurgical Industry

-

Salt/Sugar Sprinkler

Salt/Sugar Sprinkler

-

Rotary Cutter

Rotary Cutter

-

Shantui Bulldozer Track Roller

Shantui Bulldozer Track Roller

-

Oil Pipe/Tubing

Oil Pipe/Tubing

-

OCTG Couplings for Casing & Tubing

OCTG Couplings for Casing & Tubing

-

OCTG Pup Joint

OCTG Pup Joint

-

Shantui Bulldozer Carrier Roller

Shantui Bulldozer Carrier Roller

-

Cab Parts

Cab Parts