ZHJ Pump Mechanical Seal

Features

1. The ZHJ pump mechanical seal consists of a single set of primary sealing face housed in a one-piece cartridge. It allows for both forward and reverse rotations, and thus can stay unaffected by pump shaft adjustment.

2. The axial dimension of the seal should be larger than the required installation size to facilitate the removal of the set pin.

3. In order for the seal to function properly in clean water applications, the pressure of sealing water should be 0.1MPa higher than the pressure of pump chamber. The sealing water can be moved to the seal along with the media being transported.

4. Silicon carbide is embedded in the friction pair, which enables the pair to function properly at high temperatures. Depending on the nature of media transported, we can select different friction pairs ton ensure an effective, long-time service.

Applications and Operating Conditions

1. Our mechanical seal is commonly use to remove fly ash produced by the power plant, pump slurry mixtures that contain solid particles, and handle crystalizable fluids.

2. Temperature: -20℃-160℃

3. Pressure: 0-4 MPa

4. Linear Velocity: ≤15 m/s

5. Mass Concentration: ≤40%

6. Shaft Diameter: 30-280

Related Names

Propeller Shaft Seal | Fluid Sealing Supply | Pump Leakage Prevention Seal

Links:https://globefindpro.com/products/86412.html

-

ZGYX-430BD Pneumatic DTH Drilling Rig

ZGYX-430BD Pneumatic DTH Drilling Rig

-

ZQ Series Submersible Slurry Pump for Sewage Water

ZQ Series Submersible Slurry Pump for Sewage Water

-

PN Series Mud Pump

PN Series Mud Pump

-

IS, IR Series Single Stage Clean Water Pumps

IS, IR Series Single Stage Clean Water Pumps

-

ZLR Series Vertical Rubber Centrifugal Slurry Pump for Coal Washery

ZLR Series Vertical Rubber Centrifugal Slurry Pump for Coal Washery

-

QJ Series Submersible Pump

QJ Series Submersible Pump

-

ZGJ Pump Mechanical Seal

ZGJ Pump Mechanical Seal

-

Atlas Copco Hydraulic Drilling Rig

Atlas Copco Hydraulic Drilling Rig

-

ZGYX-451 Hydraulic DTH Drilling Rig

ZGYX-451 Hydraulic DTH Drilling Rig

-

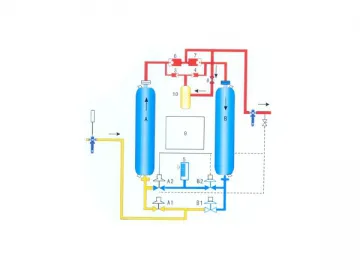

SBY Heated Desiccant Dryer

SBY Heated Desiccant Dryer

-

Combined Screw Compressor and Booster

Combined Screw Compressor and Booster

-

ZTX(R) Series Single-Stage Single-Suction Horizontal Centrifugal Desulfurization Pump

ZTX(R) Series Single-Stage Single-Suction Horizontal Centrifugal Desulfurization Pump