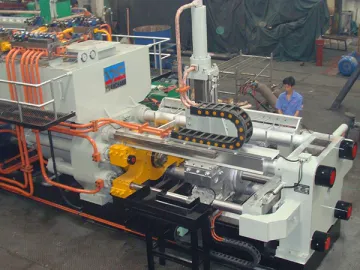

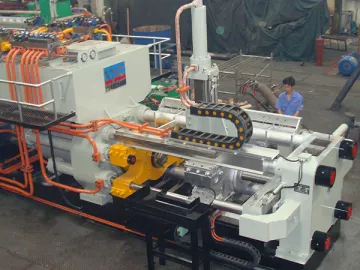

Extrusion Press (for Φ65mm Rod)

Aluminum Extrusion Machine, Rod Extruder, Aluminum Rod Extrusion Press

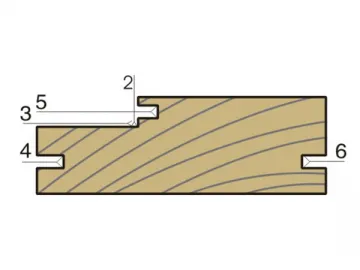

This type of rod extruder is a kind of indirect extrusion press. Different from direct extrusion press, a hollow extrusion ram containing the die is applied. While working, aluminum is forced to flow through the die in an opposite direction to the ram's motion.

Outstanding Advantages of Indirect Extrusion Press

1. Neither friction nor heat will be generated since there is no relative movement between billet and container.

2.Compared with direct extrusion press, the indirect extrusion press requires 25%~30% less extrusion force.

3. This rod extrusion press can handle profiles with a smaller cross sectional area under lower temperature, at a higher extrusion speed.

4. Uniform aluminum flow, small extrusion hole and low residual pressure by this extrusion machine ensures stable mechanical properties of profiles.

Technical Parameters

| Model (Al) | Rated pressure (MPa) | Size of standard aluminum billet (mm) | Max. circumcircle of profile (mm) | Max. width of profile (mm) | Size of die (mm) | Central height of machine (mm) | Total power (kW) | |

| Metric ton | Short ton | |||||||

| XJ-1250 | XJ-1400 | 21 | Φ152×620 | Φ65 | 65 | Φ157×100 | 1185 | 230 |

| XJ-1350 | XJ-1500 | 21 | Φ152×620 | Φ65 | 65 | Φ157×100 | 1185 | 230 |

Applications of Aluminum Rod

Aluminum rods or plates extruded by this machine enjoy fine quality and smooth surface, and most often act as curtain rails, shower cabins, shelves supports, windows & doors frames, etc.

Notes

1. Limited by the hollow raw, the applied load cannot exceed a certain range. 2. Limited by the size of die, profiles with complex cross section cannot be processed.

Links:https://globefindpro.com/products/53948.html

-

Extrusion Press (for Φ195mm Rod)

Extrusion Press (for Φ195mm Rod)

-

Extrusion Press (for Φ80mm Rod)

Extrusion Press (for Φ80mm Rod)

-

Slitting and Cut-To-Length Line for 0.3-2mm Thickness

Slitting and Cut-To-Length Line for 0.3-2mm Thickness

-

Doorframe Milling Machine

Doorframe Milling Machine

-

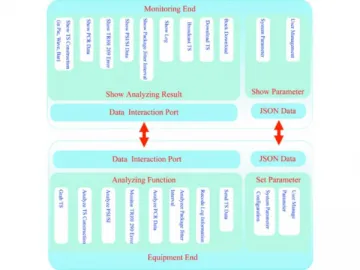

Transport Stream Analyzer

Transport Stream Analyzer

-

Stainless Steel Cut-To-Length Line

Stainless Steel Cut-To-Length Line

-

Double Action Extrusion Press for Φ180mm-Φ80mm Aluminum Seamless Tube

Double Action Extrusion Press for Φ180mm-Φ80mm Aluminum Seamless Tube

-

FZQT6-18 Block Making Machine

FZQT6-18 Block Making Machine

-

Extrusion Press (for Φ170mm Rod)

Extrusion Press (for Φ170mm Rod)

-

Extrusion Press (for Φ145mm Rod)

Extrusion Press (for Φ145mm Rod)

-

Extrusion Press (for Φ95mm Rod)

Extrusion Press (for Φ95mm Rod)

-

FZQT6-15 Block Making Machine

FZQT6-15 Block Making Machine