Small Format YAG Metal Laser Cutting Machine

1. Description:

YAG metal laser cutting machine with very thin laser beam can be used onsmall part cutting and complicated patterns and reach to a polished effect. Itsvertically cut makes the edges very smooth and neat. It also has the advantageof high cutting speed with minimal thermal distortion. Due to high accurate andnon-contact cutting, YAG laser metal cutting machine is specially applicable tothe precise accessories cutting for different thin metal materials such as mildsteel, carbon steel, stainless steel, zinc, brass ect with smooth cutting edge.

2. Features:

1) Best Cutting effect: The laser beam of laser metal cutting machine is fine andthin. It can provide the best cutting effect. Especially good in cuttingdifferent thin metal sheets.

2) High precision cutting: Apply for variety craft words and painting.

3) Fast Speed Cutting: The cutting speed is very fast up to maximum 50 mm/s.

4) Non Contact Cutting: This type cutting won’t produce any mechanicalforce or any deformation of metal sheets.

5) complicated Cutting pictures: Our laser metal cutting machine can supportvarious formats such as PDF, BMP, HPGL, JPEG, GIF, TIFF, PCX, TAG, CDR, DWG,DXF, LAS, PLT, DST, ESP, and DWG. Etc, which allows our laser metal cuttingmachine can cutting any beautiful and complicated pictures according to user’sneeds.

6) High Accuracy: YAG laser metal cutting machine can reach up to 0.001 mm.

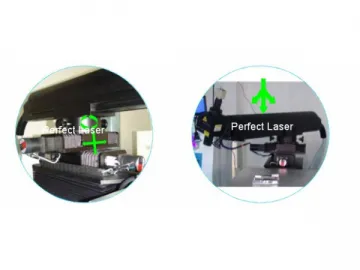

7) Auto focusing and tracking function: When metal sheet is not so plain, the machinecan adjust the focusing distance automatically.

8) Few consumables: The only consumables of laser metal cutting machine are two xenon lamps which is very cheap.

9) 5P water cooling system: Laser metal cutting machine with 5P watercooling system can cool the lens which keeps it in a suitable environment andclean situation.

10) Advanced Technology: Laser metal cutting machine adopts the currentmost advanced laser technology from Germany. It can ensure that yourmachine is the most high tech in the world.

3. Application:

YAG metal laser cutting machine ismainly used for sheet metal processing such as stainless steel cutting, mildsteel cutting, carbon steel cutting, alloy steel cutting, spring steel cutting,iron cutting, copper cutting, brass cutting, aluminum cutting, titaniumcutting, metal sheets cutting, metal plates cutting, metal pipes cutting, etc.

4. Technical Date for Laser metalCutting Machine

| Model | PE-M500-6262/PE-M700-6262 | PE-M500-2513/ PE-M700-2513 | PE-M500-3015/ PE-M700-3015 |

|

Working area mm | 620 x620mm | 2500x1300mm | 3000 x 1500mm |

| Max. Output Power | 500 W/700W | ||

| Max. cutting thickness | 0.2-8mm | ||

| Actuating Medium | Nd 3:YAG | ||

| Input Power | 16KW | ||

| Single Impulse | 10J | ||

| Laser Wave length | 1064nm | ||

| Impulse Width | 0.2~10 ms | ||

| Impulse Frequency | 0~300 Hz | ||

| Max. Cutting Speed | 20-50mm/s(1mm Stainless Steel) | ||

| Minimum Line Width | 0.4 mm | ||

| Power Stability | < ±3% | ||

| Table Axial Positioning Accuracy | 0.05 mm | ||

| Table-Driven System | Servo Motor Driver | ||

| Table Repeat Positioning Accuracy | 0.02 mm | ||

Remark: We perfect laser has the ability tocustomize any sizes according to customers’ need.

5. Optional Items:

Rotary System: this is usedfor cutting round pipe.

Air compressor dryer: This equipmentis needed when using compressed air which is the most economic way comparedwith N2 and O2.

Note from John Becker

This is the same exact information from 19-1-1.

Links:https://globefindpro.com/products/56639.html

-

Advertising Letter Laser Welding Machine

Advertising Letter Laser Welding Machine

-

AT-6200GD Dual Band Mobile Repeater / Signal Booster

AT-6200GD Dual Band Mobile Repeater / Signal Booster

-

HT8 Single Band Handheld Transceiver

HT8 Single Band Handheld Transceiver

-

HT5 Single Band Handheld Transceiver

HT5 Single Band Handheld Transceiver

-

HT12 Single Band Handheld Transceiver

HT12 Single Band Handheld Transceiver

-

CNC Channel Letter Bending Machine(Model: PEL-500)

CNC Channel Letter Bending Machine(Model: PEL-500)

-

Laser Cutting Machine for Rotary Die Making

Laser Cutting Machine for Rotary Die Making

-

AT-6000P GSM/CDMA/DCS/PCS/WCDMA Cell Phone Repeater

AT-6000P GSM/CDMA/DCS/PCS/WCDMA Cell Phone Repeater

-

Cone Crusher

Cone Crusher

-

Box Rationing Feeder

Box Rationing Feeder

-

AT-400Turbo GSM/CDMA/DCS/PCS/WCDMA Cell Phone Repeater

AT-400Turbo GSM/CDMA/DCS/PCS/WCDMA Cell Phone Repeater

-

CNC Channel Letter Bending Machine (Model: PEL-400)

CNC Channel Letter Bending Machine (Model: PEL-400)