WDW Series Computerized Electronic Universal Testing Machine

1. Equipment Usage

The WDW series electronic universal testing machine employs microprocessor control. It may carry out various tests, like tensile, compression, bend, shear, peel and tear. The testable materials can be metallic or non-metallic, such as rubber, plastics, electric wires, metal bars, panels, springs and components.

2. Measured Parameters

| Specification | Model | WDW-1A | WDW-2A | WDW-5A | WDW-1 | WDW-2 | WDW-5 |

| Measurement range of testing force (kN) | 0.01 ~1 | 0.02 ~2 | 0.05 ~5 | 0.01 ~1 | 0.02 ~2 | 0.05 ~5 |

| Accuracy of testing force | ≤1% indicating value | |||||

| Resolution rate of testing force | 1/300000 of maximum testing force; the whole process applies the same gear, or falls into 5 gears according to your needs | |||||

| Relative error of displacement | ≤0.5% indicating value | |||||

| Speed range of beam | 0.01mm /min ~500mm /min, stepless speed regulation, setting freely | |||||

| Measurement resolution of beam displacement (mm) | ≥0.001 | |||||

| Valid test space (mm) | 800 | |||||

| Supply voltage | 220V ±10% ,50Hz ; | 380V ±10% ,50Hz ; | ||||

| Working environment | Room temperature~30℃; relative humidity≤80% | |||||

| Main parts | Imported AC servomotor and speed governing system | |||||

| Main engine dimension (mm) | 600 ×420 ×1700 | |||||

| Weight (kg) | 300 | |||||

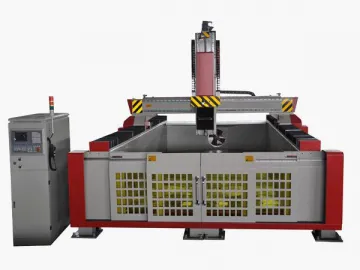

WDW Series double-column Computerized Electronic Universal Testing Machine

1. Equipment Usage

The computerized electronic universal testing machine is appropriate for rubber, plastic profiles, metal bars, panels, springs and other metallic or non-metallic testing materials. Tensile, shear, peel and other tests can be conducted. The optional test standards include GB, ISO, JIS, DIN, ASTM, etc.

2. Measured Parameters

| Specification | Model | WDW-10A | WDW-20A | WDW-10 | WDW-20 |

| Measurement range of testing force (kN) | 0.1~10 | 0.2~20 | 0.1~10 | 0.2~20 |

| Accuracy of testing force | ≤1% indicating value | |||

| Resolution rate of testing force | 1/300000 of maximum testing force; the whole process applies the same gear, or falls into 5 gears according to your needs | |||

| Relative error of displacement | ≤0.5% indicating value | |||

| Measurement resolution of beam displacement (mm) | ≥0.001 | |||

| Speed range of beam | 0.001mm/min~500mm/min, stepless speed regulation, setting freely | |||

| Valid test space (mm) | 800 | |||

| Supply voltage | 220V±10%,50Hz; | 380V±10%,50Hz; | ||

| Working environment | Room temperature~30℃; relative humidity≤80% | |||

| Main parts | Imported AC servomotor and speed governing system | |||

| Main engine dimension (mm) | 740×500×1680 | |||

| Weight (kg) | 450 | |||

3. Functions and Characteristics of Computerized Electronic Universal Testing Machine

1) With imported all-digital AC servomotor and servo driver, the product is praised for high-precision system control, stable operation and quick response.

2) Due to the precise ball screw and retarding mechanism, its drive is steady and gapless with low noise.

3) The machine adopts three-closed-loop control, and can display testing force and curves in real time. You may print these data through a printer.

Related Names

Tensile Strength Tester | Material Testing Company | Bend Test Machine

Links:https://globefindpro.com/products/61742.html

-

Door and Window Testing Machine

Door and Window Testing Machine

-

KM-100 Knurling Machine

KM-100 Knurling Machine

-

Single Axis Copy Router

Single Axis Copy Router

-

WDW-T Series Computerized Electronic Universal Testing Machine

WDW-T Series Computerized Electronic Universal Testing Machine

-

Impact Low Temperature Groove

Impact Low Temperature Groove

-

High-speed CNC Wood Router

High-speed CNC Wood Router

-

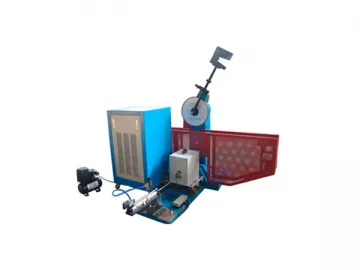

Door and Window Mechanical Property Tester

Door and Window Mechanical Property Tester

-

Laser Engraving Machine

Laser Engraving Machine

-

Shear Testing Machine

Shear Testing Machine

-

Computer Control Automatic Low Temperature Impact Testing Machine

Computer Control Automatic Low Temperature Impact Testing Machine

-

Stress Relaxation Testing Machine

Stress Relaxation Testing Machine

-

Styrofoam Machining Center

Styrofoam Machining Center