Cold Runner

The cold runner helps to save the raw material to a great extent during the manufacture of rubber products. Generally, it can increase the material utilization from the original 50%-70% to 90%, and thereby it play a significant role in various production fields. Yet, this product hasn’t be widely applied for three main reasons. One is that it requires high design and processing technologies. Secondly, the price of it is relatively high, and thirdly, it won’t well function as expected if the original design is inferior.

Main Feature

The cold runner provided by Doush adopts the integral design, which means that it is manufactured from one piece of platen by using the deep hole drill. So, it is quite different from that composed of 2 or multiple pieces of platens.

Concrete Structure

Remarkable Advantages

1. This product has a long service life.

2. Two oil temperature control systems ensure high control accuracy.

3. The smooth inner surface makes for excellent flowing property.

4. The vulcanized materials will be directly ejected, facilitating the removal of stuck materials.

5. Each product comes with terrific uniformity.

6. It also features good universality and can be applied to similar items with similar sizes.

7. It will exert better effects if it works with the other equipment or moulds of Doush.

Product Types

The custom cold runner is available according to specific requirements. The common types include the 2-cavity type, 3-cavity type, 4-cavity type, 8-cavity type, 12-cavity type, 16-cavity type, 24-cavity type and the 32-cavity type.

Product with 8 nozzles

Product debugging Product and mould

Sectional drawing of the product and the mould

Related Names

Rubber Injection Processing Machine | Custom Rubber Molding System | Rubber Trim Molding Machine

Links:https://globefindpro.com/products/80454.html

-

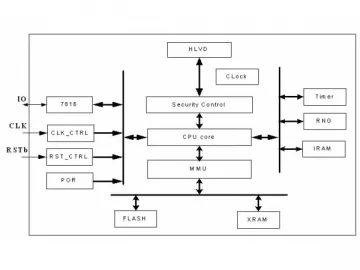

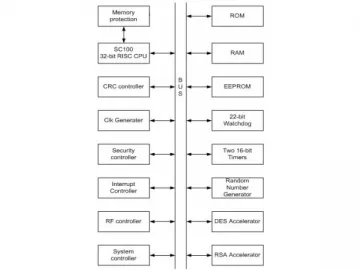

SHC1229A 104k SIM Card Chip

SHC1229A 104k SIM Card Chip

-

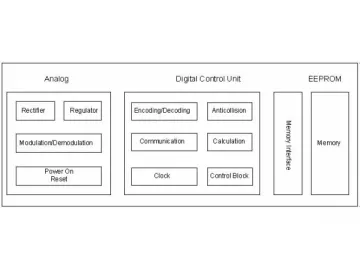

SHC1112 (SSX0904) Contactless Logic Encryption Card Chip

SHC1112 (SSX0904) Contactless Logic Encryption Card Chip

-

Solid Silicone Rubber Injection Molding Machine

Solid Silicone Rubber Injection Molding Machine

-

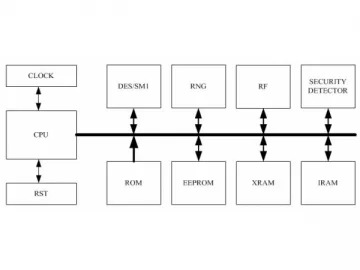

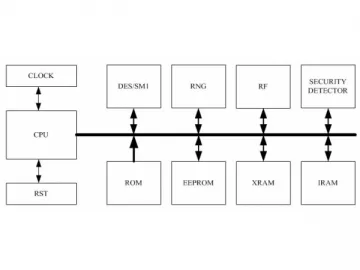

SHC1302N 32 Bit Dual Interface Credit Card Chip

SHC1302N 32 Bit Dual Interface Credit Card Chip

-

Shuttle System

Shuttle System

-

Mould Base Fixing Device

Mould Base Fixing Device

-

SHC1101 1k Bytes Contactless IC Card Chip

SHC1101 1k Bytes Contactless IC Card Chip

-

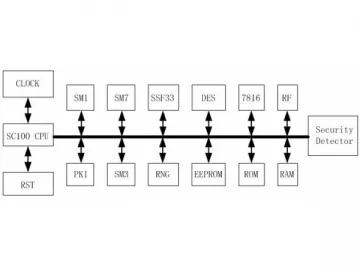

SHC1302M 32 Bit Dual Interface Credit Card Chip

SHC1302M 32 Bit Dual Interface Credit Card Chip

-

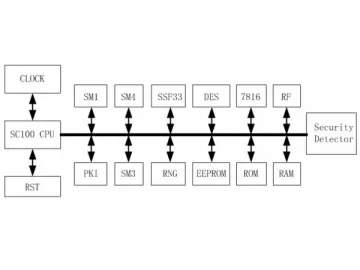

SHC1124 72k bytes PKI Based Contactless CPU Card Chip

SHC1124 72k bytes PKI Based Contactless CPU Card Chip

-

SHC1102 Contactless Single Ticket Chip

SHC1102 Contactless Single Ticket Chip

-

Mould for O Ring Seals

Mould for O Ring Seals

-

SHC1108S 8k Contactless CPU Card Chip

SHC1108S 8k Contactless CPU Card Chip