Solid Silicone Rubber Injection Molding Machine

General Introduction

The solid silicone rubber injection molding machine is extensively used for the injection manufacture of solid silicone rubber products, the production efficiency and material utilization of which are greatly higher than the mould pressing equipment.

Compared with the common similar devices, this product is fitted with silicone rubber stuffer used for pushing the solid silicone rubber into the charging barrel. The stuffer is installed at the left side of the injection unit, assisted by the hydraulic cylinder for corresponding actions.

In addition, this equipment is superbly optimized on the basis of traditional models and according to the processing characteristics of solid silicone rubber products. The optimized items include the stuffer, valve and the relevant software. This solid silicone rubber injection molding machine is ideal for manufacturing sealing elements, automobile lifting lugs, composite suspension insulators, supporting insulators, etc.

① Injection unit with standard accessories

② Silicone rubber stuffer fixed to the left side of the injection unit

Silicone rubber stuffer fixed to the left side of the injection unit

Basic Product Features

1. This solid silicone rubber injection molding machine is configured with plasticizing and injection units dedicated for the silicone rubber.

2. The screw possesses optimal exhausting, delivering and plasticizing functions.

3. The feeding device is extremely safe and pre-alarm is available for starved feeding. Double-hand manipulation is recommended.

4. The hydraulic system is high-efficiency and low energy consumed.

5. We adopt the high-efficiency KEBA control system.

6. Electrical elements of Schneider and hydraulic elements of Rexroth are applied.

Parameters

| Clamping Unit | |||||||

| Machine type | BE100 | BE160 | BE250 | BE400 | BE560 | ||

| Clamping force | kN | 1000 | 1600(1700) | 2500(2800) | 4000(4450) | 5000(5500) | |

| Opening force | kN | 38 | 58 | 58 | 93 | 94 | |

| Opening stroke | kN | 450 | 500 | 500 | 600 | 650 | |

| Max. opening between heating plates | mm | 500 | 600 | 650 | 780 | 850 | |

| Clamping speed | mm/sec | 420 | 420 | 400 | 430 | 435 | |

| Opening speed | mm/sec | 450 | 290 | 467 | 290 | 450 | |

| Lifting stroke (Stretching/retracting force) | mm(kN) | 250(24.5/14.5) | 250(40/24.5) | 250(62.8/38) | 400(98/58) | 400(98/58) | |

| Injection Unit | |||||||

| Max. injection volume | cm3 | 500 | 1000 | 2000 | 3300 | 4500 | |

| Max. injection pressure | bar | 2000 | 2130 | 2000/2200 | 2000/2240 | 2080 | |

| Max. injection capacity | cm3/sec | 60 | 80 | 135 | 135 | 205 | |

| Screw diameter | mm | 27 | 32 | 42 | 52 | 62 | |

| Screw length diameter ratio | L:D | 10:1 | 10:1 | 10:1 | 10:1 | 10:1 | |

| Max. speed/torque of screw | rpm/Nm | 220/380 | 250/540 | 213/1250 | 237/1372 | 150/1940 | |

| Plasticizing capacity | cm3/min | 400 | 600 | 1000 | 2000 | 2200 | |

| Number of heating zones | 1 | 3 | 3 | 3 | 3 | ||

| Hydraulic Unit | |||||||

| System pressure | bar | 250(280) | 250(280) | 250(280) | 250(280) | 250(280) | |

| Max. pump capacity (1450rmp) | L/min | 41 | 41 | 65 | 65 | 103 | |

| Tank volume | L | 100 | 150 | 200 | 300 | 500 | |

| Electrical Equipment | |||||||

| Motor Power | kW | 15 | 15 | 22 | 22 | 30 | |

| Heating capacity of plates | kW | 10.8 | 9.9 | 15.9 | 25.2 | 30.2 | |

| Controller voltage | V | 24 | 24 | 24 | 24 | 24 | |

| * Excluding additional mould heating | |||||||

| Mould Mounting Dimensions (mm) | |||||||

| A | Locating ring size | 80 | 110 | 110 | 110 | 110 | |

| C | Nozzle inner diameter | 4 | 4 | 6 | 8 | 8 | |

| D | Max. nozzle diameter | 6 | 6 | 10 | 12 | 12 | |

| E | Min. mould height | 50 | 100 | 150 | 180 | 200 | |

| E1 | Max. mould height | 250 | 300 | 350 | 400 | 600 | |

| F | Clear distance of columns(W) | 525 | 590 | 720 | 830 | 950 | |

| G | Clear distance of columns(L) | 270 | 295 | 380 | 600 | 710 | |

| H | Heating plate width | 360(450) | 500(570) | 600(670) | 710(810) | 810(910) | |

| I | Heating plate Length | 500(600) | 550(650) | 650(750) | 800(1200) | 1100(1300) | |

| T-slot bolt (mm) | |||||||

| Upper and bottom ejector | M12 | M12 | M12 | M16 | M16 | ||

| Heating platen | M12 | M16 | M16 | M16 | M16 | ||

| Machine Dimensions (mm) | |||||||

| A | Total height | 2840 | 2900 | 3309 | 3627 | 3980 | |

| G | Total length | 2000 | 2700 | 2700 | 3100 | 3660 | |

| N | Total width | 1120 | 1150 | 1200 | 1400 | 1680 | |

| Weight | |||||||

| Standard machines | Kg | 4100 | 5800 | 7500 | 14000 | 20000 | |

Related Names

High Temperature Vulcanized Silicone Rubber Machine | Silicone Injection Moulding Press | Thermoset Molding Equipment

Links:https://globefindpro.com/products/80457.html

-

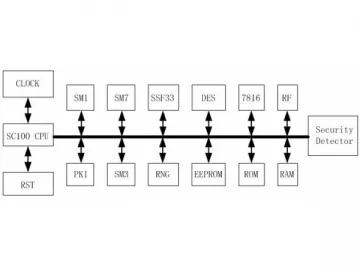

SHC1302N 32 Bit Dual Interface Credit Card Chip

SHC1302N 32 Bit Dual Interface Credit Card Chip

-

Shuttle System

Shuttle System

-

Mould Base Fixing Device

Mould Base Fixing Device

-

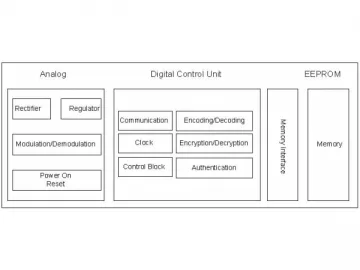

SHC1103 Contactless Single Ticket Chip

SHC1103 Contactless Single Ticket Chip

-

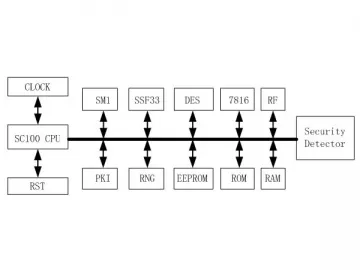

SHC1302A 32 Bit Dual Interface Credit Card Chip

SHC1302A 32 Bit Dual Interface Credit Card Chip

-

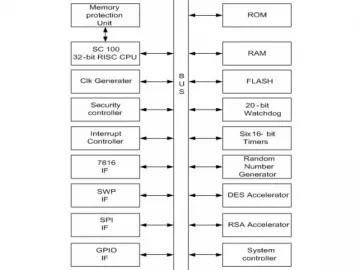

SHC1228 Mobile Payment Card Chip

SHC1228 Mobile Payment Card Chip

-

SHC1112 (SSX0904) Contactless Logic Encryption Card Chip

SHC1112 (SSX0904) Contactless Logic Encryption Card Chip

-

SHC1229A 104k SIM Card Chip

SHC1229A 104k SIM Card Chip

-

Cold Runner

Cold Runner

-

SHC1101 1k Bytes Contactless IC Card Chip

SHC1101 1k Bytes Contactless IC Card Chip

-

SHC1302M 32 Bit Dual Interface Credit Card Chip

SHC1302M 32 Bit Dual Interface Credit Card Chip

-

SHC1124 72k bytes PKI Based Contactless CPU Card Chip

SHC1124 72k bytes PKI Based Contactless CPU Card Chip