Shuttle System

You don't need to be bothered by overlong production cycle because of tedious vulcanization during rubber product manufacture for our superb shuttle system can help you to improve the efficiency. After applying it, multiplied production efficiency won't be a dream any more.

Working Principle

It contains two lower moulds and one upper mould half. When one of the lower moulds is in the state of injection and vulcanization, the other is shifted. At this time, product shifting and mould base fixing can be manually performed.

Advantages

1. For maximal process optimization, this shuttle system is also fitted with a mould handling system suitable for various machine sizes.

2. Integrated control is designed so that diagnostic and alarm messages will be displayed via the user interface.

3. It is also configured with heating platens outside the moulds to prevent the moulds from temperature reduction, so, the production efficiency and the product quality won’t be readily affected.

Related Names

Quick Mold Change System | Polymer Injection Molding Machine | Die Clamping System

Links:https://globefindpro.com/products/80459.html

-

Mould Base Fixing Device

Mould Base Fixing Device

-

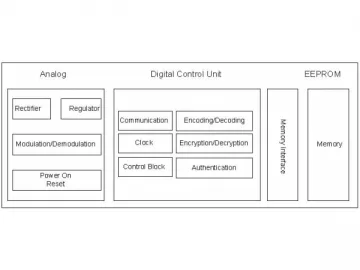

SHC1103 Contactless Single Ticket Chip

SHC1103 Contactless Single Ticket Chip

-

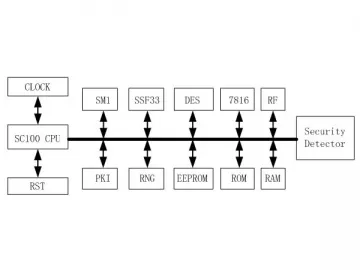

SHC1302A 32 Bit Dual Interface Credit Card Chip

SHC1302A 32 Bit Dual Interface Credit Card Chip

-

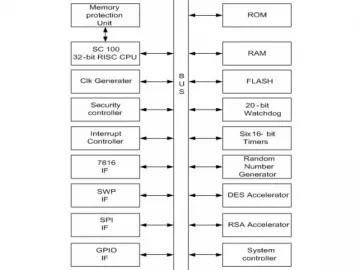

SHC1228 Mobile Payment Card Chip

SHC1228 Mobile Payment Card Chip

-

Rubber Injection Compression Molding Machine

Rubber Injection Compression Molding Machine

-

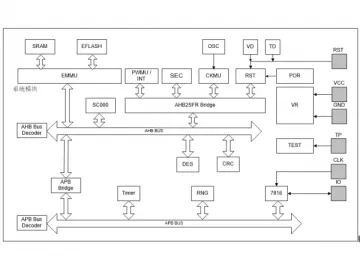

SHC1232 32k EEPROM Contact Social Security Card Chip

SHC1232 32k EEPROM Contact Social Security Card Chip

-

SHC1302N 32 Bit Dual Interface Credit Card Chip

SHC1302N 32 Bit Dual Interface Credit Card Chip

-

Solid Silicone Rubber Injection Molding Machine

Solid Silicone Rubber Injection Molding Machine

-

SHC1112 (SSX0904) Contactless Logic Encryption Card Chip

SHC1112 (SSX0904) Contactless Logic Encryption Card Chip

-

SHC1229A 104k SIM Card Chip

SHC1229A 104k SIM Card Chip

-

Cold Runner

Cold Runner

-

SHC1101 1k Bytes Contactless IC Card Chip

SHC1101 1k Bytes Contactless IC Card Chip