Rubber Injection Compression Molding Machine

General Introduction

The rubber injection compression molding machine is specially designed for customers requiring mass production and small injection volume. It can manufacture a great many products at one time by utilizing a small quantity of raw materials, which greatly improves product properties and material utilization, increases production output and also effectively reduces the cost investment of customers.

Currently, this equipment is widely used for producing oil seals, O type rings and other sealing elements. Besides, with the advantages of fast high-temperature vulcanization, raw material saving and high automaticity, it gradually replaces the curing press in the rubber processing industry.

Design Innovation

Except the above mentioned advantages, the rubber injection compression molding machine is also novel in design.

1. There is a heating device inside the upper mould platen, which can promote the rubber vulcanization and shorten the cycle duration.

2. The upper mould plate is designed with several transfer injection runners for maximally saving the raw materials. Besides, each mould cavity comes with the same number of runners, thus the product uniformity is largely enhanced.

Remarkable Features

1. This rubber injection compression molding machine can be used to manufacture small precision products without the runner waste or the cured rubber waste.

2. One-time feeding is sufficient for continuous injection and compression.

3. It enables evacuation, ejection and automatic control.

4. Injection and compression metering is accurate.

5. The temperature of heating platens is controlled within ±3°C.

6. The pressure for mould clamping and the integral running are stable.

7. The rubber injection compression molding machine is fitted with imported heating tubes and electric components.

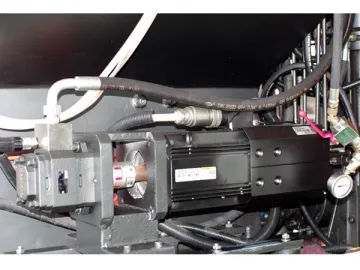

8. It comes with the variable pump drive from Rexroth, high-pressure oil pipes and precise pipe joints.

Technical Parameters

| Tonnage | 60T | 100T | 200/250T |

| Type | Manual feeding, continuous injection | Manual feeding, continuous injection | Manual feeding, continuous injection |

| Transfer Unit | |||

| Cylinder type | Reciprocating cylinder | Reciprocating cylinder | Reciprocating cylinder |

| Main cylinder Diameter (mm) | Φ205 | Φ250 | Φ360 |

| Piston outer diameter (mm) | Φ204 | Φ220 | Φ300 |

| Stroke (mm) | 185 | 150-200 | 200 |

| Temperature of the charging barrel (°C) | 30-120 | 30-120 | 30-120 |

| Temperature control tolerance (°C) | ±1 | ±1 | ±1 |

| Mould Clamping Unit | |||

| Clamping force (KN) | 200-600 | 200-1000 | 200-2000 |

| Heating platen size (mm) | 190×189×45 | 230×230×40 | 450×450×60 |

| Heating platen parallelism (mm) | 0.05 | 0.05 | 0.05 |

| Heating time (60 min.) | Ambient temperature to 200°C | Ambient temperature to 200°C | Ambient temperature to 200°C |

| Heating power (KW) | 1.7/3.2 | 3.0/3.2 | 4.8 |

| Temperature control of the heating platen | 1 zone | 1 zone | 1 zone |

| Temperature tolerance of the heating platen (°C) | ±5 | ±5 | ±5 |

| Vacuumizing | Mold | Mold | Mold |

| Vacuumizing time (700mmHg) | 6s | 10s | 10s |

| Mould Sliding Unit | |||

| Motion Pattern | Cylinder drive/servo motor | Cylinder drive/servo motor | Cylinder drive/servo motor |

| Stroke (mm) | 550 | 400 | 550 |

| Pushing force (kg) | 40 | 40 | 40 |

| Speed (adjustable) | 3s | 3s | 3s |

| Others | |||

| Working height (mm) | 1030 | 800 | 800 |

| Size (L×W×H) (mm) | 2190×1215×1935 | 1800×2100×1970 | |

| Total power (KW) | 9.5 | 25.97 | |

| Net weight (kg) | 2500 | 3450 | 4600 |

Related Names

Compression Molding Press | Rubber Hot Press Machine | Precision Injection Molding Equipment

Links:https://globefindpro.com/products/80465.html

-

SHC1232 32k EEPROM Contact Social Security Card Chip

SHC1232 32k EEPROM Contact Social Security Card Chip

-

Mould for Home Appliance

Mould for Home Appliance

-

SHC1220S 140k SIM Card Chip

SHC1220S 140k SIM Card Chip

-

SHC1216 16k EEPROM Contact Social Security Card Chip

SHC1216 16k EEPROM Contact Social Security Card Chip

-

SE Series Rubber Injection Molding Machine

SE Series Rubber Injection Molding Machine

-

SHC2242 2k Bits EEPROM Contact Encryption Chip

SHC2242 2k Bits EEPROM Contact Encryption Chip

-

SHC1228 Mobile Payment Card Chip

SHC1228 Mobile Payment Card Chip

-

SHC1302A 32 Bit Dual Interface Credit Card Chip

SHC1302A 32 Bit Dual Interface Credit Card Chip

-

SHC1103 Contactless Single Ticket Chip

SHC1103 Contactless Single Ticket Chip

-

Mould Base Fixing Device

Mould Base Fixing Device

-

Shuttle System

Shuttle System

-

SHC1302N 32 Bit Dual Interface Credit Card Chip

SHC1302N 32 Bit Dual Interface Credit Card Chip