SE Series Rubber Injection Molding Machine

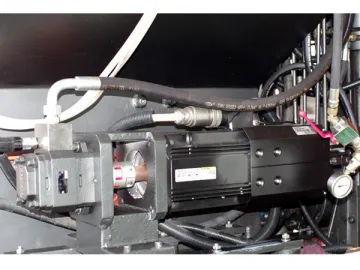

Servo drive of Rexroth

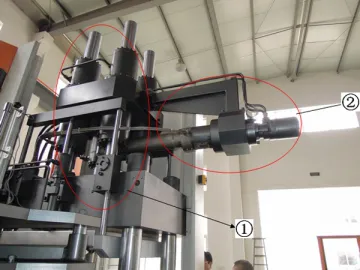

The SE series rubber injection molding machine can be manufactured with 2 types of power systems, including the servo motor of Rexroth and the constant delivery pump of Rexroth. Attached with many optional items, both of the 2 power systems is accurate and energy-saving. Their advantages like prompt response, high position repeatability and quiet running make for more superior production.

As a global leader, the servo motor of Rexroth outputs according to the required pressure and flow volume to reduce idling energy consumption, thus greatly lowering your electric power cost. The energy dissipation coefficient of this rubber injection molding machine is only about 0.03, and the power consumed is only 35%-50% of other power systems under the same conditions.

By virtue of various advantages, this rubber injection molding machine will be increasingly widespread and favored by more customers. It will immensely reduce your cost in energy investment, and its rapid response and high repeat accuracy make it the best choice for manufacturing high-precision oil seals. What’s more, you will love to work with it due to its admirable running quietness.

Parameters

| Clamping Unit | |||||||

| Machine type | BE100 | BE160 | BE250 | BE400 | BE560 | ||

| Clamping force | kN | 1000 | 1600(1700) | 2500(2800) | 4000(4450) | 5000(5500) | |

| Opening force | kN | 38 | 58 | 58 | 93 | 94 | |

| Opening stroke | kN | 450 | 500 | 500 | 600 | 650 | |

| Max. opening between heating plates | mm | 500 | 600 | 650 | 780 | 850 | |

| Clamping speed | mm/sec | 420 | 420 | 400 | 430 | 435 | |

| Opening speed | mm/sec | 450 | 290 | 467 | 290 | 450 | |

| Lifting stroke (Stretching/retracting force) | mm(kN) | 250(24.5/14.5) | 250(40/24.5) | 250(62.8/38) | 400(98/58) | 400(98/58) | |

| Injection Unit | |||||||

| Max. injection volume | cm3 | 500 | 1000 | 2000 | 3300 | 4500 | |

| Max. injection pressure | bar | 2000 | 2130 | 2000/2200 | 2000/2240 | 2080 | |

| Max. injection capacity | cm3/sec | 60 | 80 | 135 | 135 | 205 | |

| Screw diameter | mm | 27 | 32 | 42 | 52 | 62 | |

| Screw length diameter ratio | L:D | 10:1 | 10:1 | 10:1 | 10:1 | 10:1 | |

| Max. speed/torque of screw | rpm/Nm | 220/380 | 250/540 | 213/1250 | 237/1372 | 150/1940 | |

| Plasticizing capacity | cm3/min | 400 | 600 | 1000 | 2000 | 2200 | |

| Number of heating zones | 1 | 3 | 3 | 3 | 3 | ||

| Hydraulic Unit | |||||||

| System pressure | bar | 250(280) | 250(280) | 250(280) | 250(280) | 250(280) | |

| Max. pump capacity (1450rmp) | L/min | 41 | 41 | 65 | 65 | 103 | |

| Tank volume | L | 100 | 150 | 200 | 300 | 500 | |

| Electrical Equipment | |||||||

| Motor Power | kW | 15 | 15 | 22 | 22 | 30 | |

| Heating capacity of plates | kW | 10.8 | 9.9 | 15.9 | 25.2 | 30.2 | |

| Controller voltage | V | 24 | 24 | 24 | 24 | 24 | |

| * Excluding additional mould heating | |||||||

| Mould Mounting Dimensions (mm) | |||||||

| A | Locating ring size | 80 | 110 | 110 | 110 | 110 | |

| C | Nozzle inner diameter | 4 | 4 | 6 | 8 | 8 | |

| D | Max. nozzle diameter | 6 | 6 | 10 | 12 | 12 | |

| E | Min. mould height | 50 | 100 | 150 | 180 | 200 | |

| E1 | Max. mould height | 250 | 300 | 350 | 400 | 600 | |

| F | Clear distance of columns(W) | 525 | 590 | 720 | 830 | 950 | |

| G | Clear distance of columns(L) | 270 | 295 | 380 | 600 | 710 | |

| H | Heating plate width | 360(450) | 500(570) | 600(670) | 710(810) | 810(910) | |

| I | Heating plate Length | 500(600) | 550(650) | 650(750) | 800(1200) | 1100(1300) | |

| T-slot bolt (mm) | |||||||

| Upper and bottom ejector | M12 | M12 | M12 | M16 | M16 | ||

| Heating platen | M12 | M16 | M16 | M16 | M16 | ||

| Machine Dimensions (mm) | |||||||

| A | Total height | 2840 | 2900 | 3309 | 3627 | 3980 | |

| G | Total length | 2000 | 2700 | 2700 | 3100 | 3660 | |

| N | Total width | 1120 | 1150 | 1200 | 1400 | 1680 | |

| Weight | |||||||

| Standard machines | Kg | 4100 | 5800 | 7500 | 14000 | 20000 | |

Related Names

Precision Moulding Machine | Vertical Molding Equipment | Rubber Vulcanizing Equipment

Links:https://globefindpro.com/products/80470.html

-

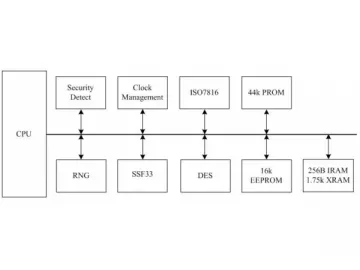

SHC2242 2k Bits EEPROM Contact Encryption Chip

SHC2242 2k Bits EEPROM Contact Encryption Chip

-

HZ Series Rubber Injection Molding Machine

HZ Series Rubber Injection Molding Machine

-

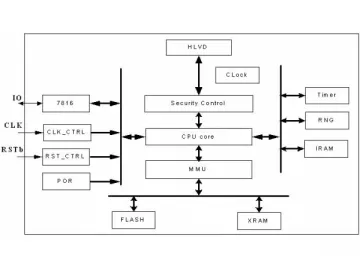

SHC1237 220k SIM Card Chip

SHC1237 220k SIM Card Chip

-

Mould for Auto Bush

Mould for Auto Bush

-

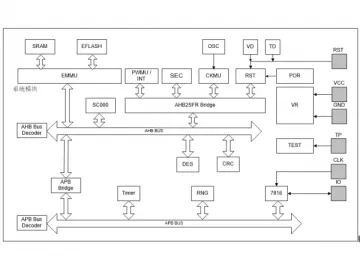

SHC1302F 32 Bit Dual Interface Credit Card Chip

SHC1302F 32 Bit Dual Interface Credit Card Chip

-

Mould for Silicone Rubber Products

Mould for Silicone Rubber Products

-

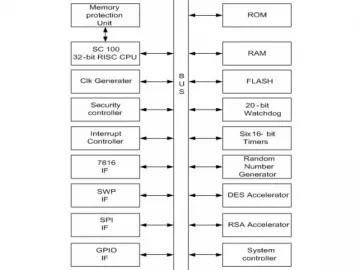

SHC1216 16k EEPROM Contact Social Security Card Chip

SHC1216 16k EEPROM Contact Social Security Card Chip

-

SHC1220S 140k SIM Card Chip

SHC1220S 140k SIM Card Chip

-

Mould for Home Appliance

Mould for Home Appliance

-

SHC1232 32k EEPROM Contact Social Security Card Chip

SHC1232 32k EEPROM Contact Social Security Card Chip

-

Rubber Injection Compression Molding Machine

Rubber Injection Compression Molding Machine

-

SHC1228 Mobile Payment Card Chip

SHC1228 Mobile Payment Card Chip