QTJ4-25 Block Making Machine

The block making machine is designed on the basis of market requirements. As a mechanical drive block machine, it innovatively adopts PLC and realizes fully-automatic operation, including pallet conveying, material feeding, block output and so on, which greatly reduces labor intensity. With the molding cycle of 25 seconds, it is capable of producing 7720 blocks every 8 hours.

Features

1. Since the block making machine increases pressure from up and down sides, and vibrates intensively, it is perfect for manufacturing high-strength blocks that support instant stacking for 3-5 layers after molding.

2. The PLC system makes use of the high-quality domestic electronic components. It can give clear instructions, automatically detect errors, and intelligently disconnect the equipment if there is a malfunction, which helps to prolong service life.

3. Its multifunctional material feeding system is equipped with mixing forks, so as to forcibly stir solidified raw materials for the second time. The continuous and reciprocating feeding mode brings about uniform and all-sided feeding, and ensures high compactness and good neatness of blocks.

4. On the basis of the spot welding technology, the super steel frame of this cement block maker achieves seamless welding and looks smooth.

| Productive capacity | 400x200x200mm: 4840 PCS /8h 400x150x200mm: 5800 PCS/8h 400x100x200mm: 7720 PCS/8h |

| Power | 21 kw |

| Overall size | 3000X1950X2400mm |

| Cycle | 25 s |

| Pallet size | 850x470x30mm |

| Vibration force | 450KN |

| Vibration frequency | 4000-4800/Minute |

| Nominal pressure | 14Mpa |

| Total weight | 5000kg |

| Power source | 380v/50HZ |

Links:https://globefindpro.com/products/80533.html

-

QTJ4-26A Block Making Machine

QTJ4-26A Block Making Machine

-

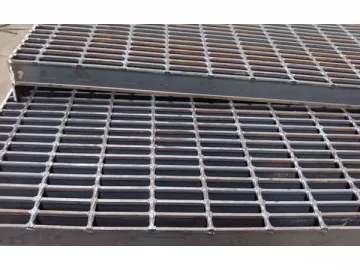

Floor Gratings for Platform

Floor Gratings for Platform

-

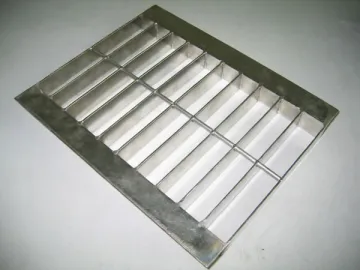

I Bar Gratings

I Bar Gratings

-

QT4-15A Fully-Automatic Concrete Block Production Line

QT4-15A Fully-Automatic Concrete Block Production Line

-

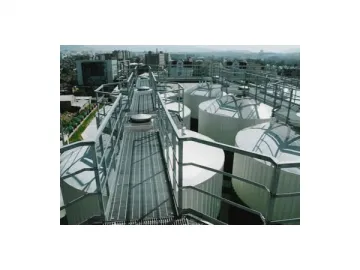

Stainless Steel Gratings, Aluminum Grating

Stainless Steel Gratings, Aluminum Grating

-

Press-locked Gratings

Press-locked Gratings

-

QFT5-20 Block Making Machine

QFT5-20 Block Making Machine

-

QMR2-45 Mobile Block Making Machine

QMR2-45 Mobile Block Making Machine

-

Steel Structures

Steel Structures

-

SY-800 Vertical Concrete Pipe Making Machine

SY-800 Vertical Concrete Pipe Making Machine

-

Slitting Machine

Slitting Machine

-

Twisted Cross Bar Making Machine

Twisted Cross Bar Making Machine