QTJ4-26A Block Making Machine

The QTJ4-26A block making machine adopts the semi-automatic loading and unloading system, so as to decrease labor force. It comes with mechanical drive, strong vibration effect and low power of 10.35W, which enables the molding flask to be filled with raw materials. In addition, since the upper mold vibrates for pressurization, produced blocks are proud of uniform density, high strength and great performance. Equipped with the automatic conveying system, the machine may automatically convey the blocks to the pallet truck. Its molding cycle is 26 seconds, and its output is 6720 PCS every 8 hours.

Features

1. The motor is designed in the lower part of the block making machine, so as to improve chassis stability and leave out laying foundation.

2. Its motor drives the lower part of the vibrating case powerfully, and the upper part makes use of a traditional vibrator with good durability.

3. The mould is propelled in place by the motor, which realizes occupying the position seamlessly and leaving the position smoothly. In this way, mould abrasion is reduced and its working life is prolonged.

4. Appropriate raw materials for blocks include clay, coal ash, sandy clay, red soil, gangue, shale, sludge, sand, stone, construction waste, slag, etc.

| Productive capacity | 400x200x200mm: 3840 PCS /8h 400x150x200mm: 4800 PCS/8h 400x100x200mm: 6720 PCS/8h |

| Power | 10.35kw |

| Overall size | 2050X1740X2650mm |

| Cycle | 26 s |

| Pallet size | 850x470x30mm |

| Vibration force | 40KN |

| Vibration frequency | 4000-4800/Minute |

| Nominal pressure | 12Mpa |

| Total weight | 2500kg |

| Power source | 380v/50HZ |

Related Names

26s Molding Cycle Block Machine | Construction Material Manufacturing Machinery | Brick Machine

Links:https://globefindpro.com/products/80534.html

-

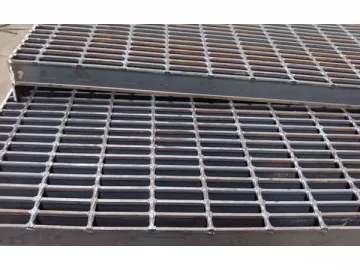

Floor Gratings for Platform

Floor Gratings for Platform

-

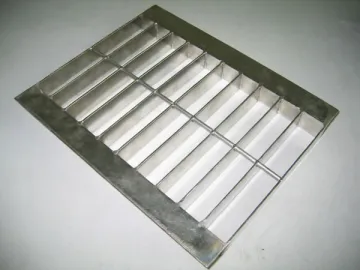

I Bar Gratings

I Bar Gratings

-

QT4-15A Fully-Automatic Concrete Block Production Line

QT4-15A Fully-Automatic Concrete Block Production Line

-

Stainless Steel Gratings, Aluminum Grating

Stainless Steel Gratings, Aluminum Grating

-

Press-locked Gratings

Press-locked Gratings

-

Standard Gratings

Standard Gratings

-

QTJ4-25 Block Making Machine

QTJ4-25 Block Making Machine

-

QFT5-20 Block Making Machine

QFT5-20 Block Making Machine

-

QMR2-45 Mobile Block Making Machine

QMR2-45 Mobile Block Making Machine

-

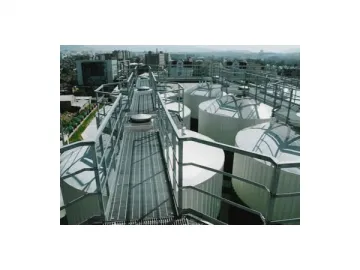

Steel Structures

Steel Structures

-

SY-800 Vertical Concrete Pipe Making Machine

SY-800 Vertical Concrete Pipe Making Machine

-

Slitting Machine

Slitting Machine