QT4-15A Fully-Automatic Concrete Block Production Line

The QT4-15A fully-automatic concrete block production line can be fitted with different moulds to produce concrete blocks with various specifications, such as hollow block, multi-hole brick, solid brick, paver, Dutch brick, curbstone, concrete element and other blocks used in buildings, roads , parks, airport, wharfs and so forth.

With 15s molding cycle, the concrete block production line is able to manufacture 15360 pieces every 8 hours. Therefore, it is ideal for mass production. The finished blocks comes with excellent quality, high strength, great compressive strength, good compactness,exact dimension, desirable anti-permeability and freezing resistance. The production line may be comprised of different devices to satisfy your demands.

Features

1. Its automatic block making machine adopts PLC and supports computer operation, random signal analysis, fault diagnosis and material parameter setting.

2. The concrete block production line is equipped with a storage hopper and a feed hopper. Feeding in a fixed quantity can effectively prevent a part of concrete solidifying in advance and reduce charging time. Its automatic stacker helps to save considerable labor force and production area.

3. The unique feeding device is capable of quickly and uniformly pour materials into the molding flask, so as to minimize the weight error of finished blocks.

4. The super steel rack and imported electro-hydraulic components contribute to the stability of production line.

| Productive capacity | 400x200x200mm: 6100 PCS /8hour 400x150x200mm: 9600 PCS/8hour 400x100x200mm: 15360 PCS/8hour |

| Power | 29.4 kw |

| Overall size | 3700X1500X2600mm |

| Cycle | 15s |

| Pallet size | 900x550x30mm |

| Vibration force | 50KN |

| Vibration frequency | 4000-4800/Minute |

| Nominal pressure | 16Mpa |

| Total weight | 6500kg |

| Power source | 380v/50HZ |

Related Names

Automatic Block Making Machine | Paver Production Line | Building Material Making Machines

Links:https://globefindpro.com/products/80537.html

-

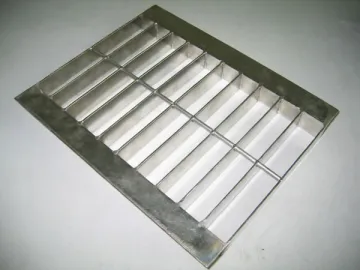

Stainless Steel Gratings, Aluminum Grating

Stainless Steel Gratings, Aluminum Grating

-

Press-locked Gratings

Press-locked Gratings

-

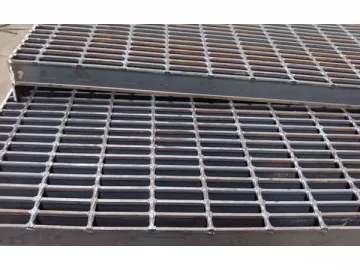

Standard Gratings

Standard Gratings

-

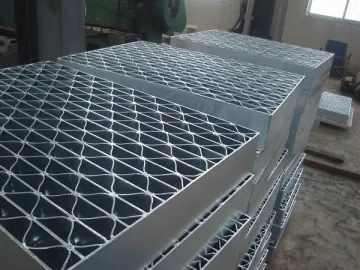

Steel Mesh Gratings

Steel Mesh Gratings

-

Custom Made Gratings

Custom Made Gratings

-

SY-2000 Horizontal Concrete Pipe Making Machine

SY-2000 Horizontal Concrete Pipe Making Machine

-

I Bar Gratings

I Bar Gratings

-

Floor Gratings for Platform

Floor Gratings for Platform

-

QTJ4-26A Block Making Machine

QTJ4-26A Block Making Machine

-

QTJ4-25 Block Making Machine

QTJ4-25 Block Making Machine

-

QFT5-20 Block Making Machine

QFT5-20 Block Making Machine

-

QMR2-45 Mobile Block Making Machine

QMR2-45 Mobile Block Making Machine