Traverse Traveling Head Shaping Machine

Application

The traverse traveling head shaping machine suiting single-piece or batched production is designed for the machinery, metallurgy and other manufacturing industries. It is used for planing the large-sized or heavy-duty workpieces that have various flat, grooved or specially shaped surfaces.

Features

1. The main cutting motion and the feed motion are hydraulically driven. Stepless speed adjustment and the hydraulic overload protection device are adopted. Therefore, the transmission is steady and reliable.

2. This equipment has large cutting capacity, high rigidity, low oil temperature, small thermal deformation and stable accuracy.

3. The slide carriage is capable of transversely automatic feed and rapid movement.

4. The tool post of the traverse traveling head shaping machine is equipped with automatic cutter lifting and feed mechanisms, allowing for convenient operation.

Technical Parameters

| Item | B100A | B125 | Unit |

| Maximum planing length × width | 1000×1500-2000 | 1250×1500-2000 | mm |

| Ram stroke | 80-1000 | 80-1250 | mm |

| Maximum distance from ram bottom to working table surface | 1200 | 1200 | mm |

| Maximum stroke of tool post | 160 | 160 | mm |

| Maximum sectional area of cutter bar (width × height) | 30×45 | 30×45 | mm |

| Maximum rotation angle of tool post | ±60 ゚ | ±60 ゚ | |

| Working surface size (length × width) | 1000×2000 | 1250×2000 | mm |

| T-type groove width of working table | 28 | 28 | mm |

| Lateral feed range of slide carriage (stepless) | 0.25-3 | 0.25-3 | mm |

| Main motor | 7.5 | 7.5 | KW |

| Quick motor | 1.5 | 1.5 | KW |

| Overall dimension (length × width × height) | 3605×3175×2605 | 3605×3400×2605 | mm |

| Net weight (approximate) | 8000 | 8400 | kg |

Related Names

Metal Surface Planing Equipment | Machine Parts Shaper | Metalworking Planer

Links:https://globefindpro.com/products/81347.html

-

Universal Milling Machine

Universal Milling Machine

-

EMM23 Series C-Frame Inclinable Mechanical Presses

EMM23 Series C-Frame Inclinable Mechanical Presses

-

Drilling and Milling Machine

Drilling and Milling Machine

-

Section Bender

Section Bender

-

EMH21 Series C-frame Fixed Bolster Pneumatic Presses

EMH21 Series C-frame Fixed Bolster Pneumatic Presses

-

Hydraulic Shaping Machine

Hydraulic Shaping Machine

-

Hand Operated Riveting Machine

Hand Operated Riveting Machine

-

PU Foam Machine

PU Foam Machine

-

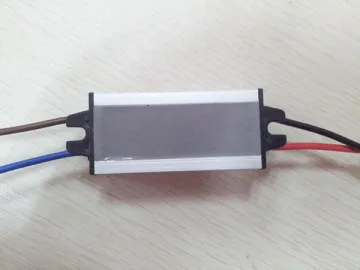

8W-12W Constant Current LED Driver

8W-12W Constant Current LED Driver

-

10W-25W Constant Current LED Driver

10W-25W Constant Current LED Driver

-

8W-20W Waterproof LED Driver

8W-20W Waterproof LED Driver

-

12W Constant Current LED Driver

12W Constant Current LED Driver