Universal Milling Machine

The universal milling machine working with various types of cutters, such as the rod type, round type and the angular type, is used for processing workpieces with flat, angular, grooved or other surfaces. Once it is configured with the universal cutter head, round working table, the indexing head and other accessories, the working range will be tremendously expanded. With excellent stiffness, large power and strong working capacity, this equipment is built for high-speed, heavy-duty cutting work and gear machining.

We'd like to briefly introduce three main models for your reference:

1. The US436C universal milling machine with large stroke enables both vertical and horizontal milling. The Z axis can be manually operated, reaching 600mm stroke with good stability. Besides, this product features two axis feeding, Z-axis electric lifting and three-axis hardening treatment.

2. The US432B adopts the square sildeway in Y axis. The working table enables 45-degree rotation, and the three axis is processed with hardening.

3. The US426 is configured with a stand-alone horizontal milling unit on the basis on original vertical milling function. It adopts gear transmission and two axis feed. The Z axis can be equipped with lifting system according to the requirements of customers. With the new configuration, this product gets rid of the power shortage defect and breaks the original processing limitation. Additionally, it also comes with hardened three axis.

Technical Parameters

| Item | US436C | US436A |

| Working table size (mm) | 1250×360 | 1630×360 or 1800×360 (optional) |

| T-type groove (numbers, width, space) (mm) | 3/16/80 | 3/18/80 |

| Maximum bearing capacity of working table | 300kg | 350 |

| Working table stroke (mm) | 970 (1000)/300/390 | 1000/1200 (optional)×320 ×420 |

| Feed speed | 15/370 vertical milling | 30/55/100/190/350/630/2000 |

| 15/370 horizontal milling | ||

| Cutting speed | 660/660/760mm/min. | |

| Spindle taper for vertical milling | IS040 | ISO50 (V) |

| Spindle taper for horizontal milling | IS040 | ISO50 (H) |

| Speed grade | 12 | 12 |

| Spindle speed | 35-1600 (V) | 60-1800 (H) (12 steps) |

| 40-1300 (H) | 60-1700 (V) (12steps) | |

| Front bearing diameter (mm) | 90 | |

| Motor power | 3KW | 4KW (H) 4KW (V) |

| Feeding motor power | XY/0.75KW Z/1.1KW | 1.5KW |

| Distance from horizontal shaft to table surface (mm) | 0-420 | 0-480 |

| Distance from spindle center to slideway (mm) | 505 | |

| Ram movement distance (mm) | 0-500 | |

| Distance from vertical shaft to table surface (mm) | 150-690 | |

| Vertical shaft stroke (mm) | 350-850 | |

| Rotation angle of cutter head | 360º | 360° |

| Maximum facer diameter (mm) | 125 (V)-100 (H) | |

| Packing size (mm) | 1750×1700×2250 | 2000×2000×2250 |

| Net/gross weight (kg) | 2650/2850 | 2950/3000 |

| Item | Unit | US432B | US426 | UM426B without horizontal milling | UM426A without horizontal milling |

| Maximum width for end milling | mm | 125 | 125 | ||

| Maximum horizontal milling diameter | mm | 100 | 125 | ||

| Maximum vertical milling diameter | mm | 28 | 28 | 25 | 25 |

| Distance from spindle center to table surface (mm) | mm | 100-500 | 560 | 80-500mm | 80-500 |

| Spindle speed | RPM | 35-1600 vertical milling | 35-1600 | 40-1600 | 40-1600 |

| 40-1300 (12) horizontal milling | 40-1300 horizontal milling | ||||

| Rotation angle of cutter head | ± 360° | ± 360° | 360° | 360° | |

| Ram stroke | 420 | ||||

| Working table size | mm | 1250×320 | 1270×260 | 1120×260 | 1120×260 |

| Working table stroke | mm | 600× 340 × 350 | 750×300 | 600×270 | 600×270 |

| Packing size (mm) | mm | 1550×1650×2200 | 1550×1650×2200 | 1650×1550×2200 | 1655×1500×1730 |

| Motor power | KW | 3 | 3 (H) 3 (V) | 2.2 | 2.2 |

| Net/gross weight (kg) | kg | 1550/1700 | 1480/1660 | 1400/1600 | 1400/1600 |

| Spindle taper | ISO40 |

Related Names

Round Rod Milling Machine | Slot Milling Equipment | Milling Cutting Tool

Links:https://globefindpro.com/products/81348.html

-

EMM23 Series C-Frame Inclinable Mechanical Presses

EMM23 Series C-Frame Inclinable Mechanical Presses

-

Drilling and Milling Machine

Drilling and Milling Machine

-

Section Bender

Section Bender

-

EMH21 Series C-frame Fixed Bolster Pneumatic Presses

EMH21 Series C-frame Fixed Bolster Pneumatic Presses

-

Hydraulic Shaping Machine

Hydraulic Shaping Machine

-

Single Cylinder Hydraulic Ironworker

Single Cylinder Hydraulic Ironworker

-

Traverse Traveling Head Shaping Machine

Traverse Traveling Head Shaping Machine

-

Hand Operated Riveting Machine

Hand Operated Riveting Machine

-

PU Foam Machine

PU Foam Machine

-

8W-12W Constant Current LED Driver

8W-12W Constant Current LED Driver

-

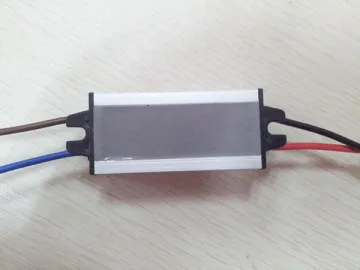

10W-25W Constant Current LED Driver

10W-25W Constant Current LED Driver

-

8W-20W Waterproof LED Driver

8W-20W Waterproof LED Driver