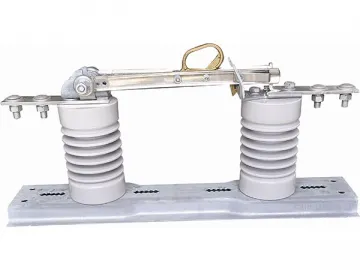

(H)GW9 Outdoor High Voltage AC Disconnector

The (H)GW9 outdoor high voltage AC disconnector is used to cut off electrical appliances in a three-phase 12kV power distribution system of rural or urban power grid in case of no load. It is simple in structure and convenient as well as economical to use.

This outdoor disconnector has a single fracture vertical open style structure. It is mainly composed of the base, post insulator, conductive portion, and operating mechanism. The post insulator, either porcelain housed or silicone rubber housed, is mounted on the base. A switch blade structure is used for the cutting off and closing of lines. Each switch blade consists of two conductive sheets and a compression spring is installed in each side of the sheet. Adjusting the height of the spring can change the contact pressure required to switch the blade. An insulated hookstick is used to open and close the disconnecting switch. When the switch is closed, the self-lock device will come into play.

Action Principle

The switching of the disconnector is completed by an insulated hookstick. The hookstick clasps the latch hook and pulls the latch hook towards the opening direction. After the self-lock device is unfastened, the conductive plate is driven to rotate, so as to realize the opening operation. When closing, the hookstick fixes the latch lock and drives the shaft to rotate. Then, the conductive plate rotates to the closing position. Afterwards, the self-lock device locks the disconnector in the closing position.

Installation

This high voltage AC disconnector can be mounted on the pillar, wall, ceiling, or cross beam. It can be installed in two ways, i.e., vertical installation and horizontal installation. Hence, the opening angle of the main blade has two different values. Before the delivery of this switch, the locating pin of main blade is installed in such a position that the opening angle is 160 degrees. For the switch supposed to be installed inversely, the locating pin can be moved to the position that makes the opening angle of the main blade reach 90 degrees. This can be easily realized as follows. Move the cotter pin at the end of the locating pin; move the locating pin to the adjacent pin hole; and use the cotter pin to fix the locating pin.

Technical Parameters of (H)GW9 Outdoor High Voltage AC Disconnector

| Items | Units | Value | |||||||

| Rated voltage | kV | 10 | 12 | 15 | |||||

| Max. operating voltage | kV | 12 | 15 | 17.5 | |||||

| Rated insulation level | 1min. Power frequency withstand voltage (RMS) | To earth | kV | 28 | 38 | 40 | |||

| Between fractures | kV | 32 | 42 | 47 | |||||

| Rated lightning impulse withstand voltage (peak) | To earth | kV | 60 | 75 | 105 | ||||

| Between fractures | kV | 70 | 85 | 120 | |||||

| Rated frequency | Hz | 50 | |||||||

| Rated current | A | 200 | 400 | 630 | 1250 | ||||

| 4s thermal stability current (RMS) | kA | 6.3 | 12.5 | 20 | 31.5 | ||||

| Dynamic stability current (peak) | kA | 16 | 31.5 | 50 | 80 | ||||

| Mechanical life | times | 2000 | |||||||

Component Description

1. The blade stop pin is set with an opening of 160 degrees when leaving the factory, but it can be readily reset with a 90-degree opening in the field.

2. Double-deck cold-drawn silver-plated copper blade with round edge

3. The copper pull ring with locking device can be freely operated in any angle.

4. The contact is silver-to silver, backed up by stainless steel loading springs.

5. Bolt used to fix the insulator, preventing slipping or rotating of live parts, especially during closing from the side

6. Outdoor epoxy insulating post

7. Hot dip galvanized mounting plate

8. Terminal board

The GW9 outdoor AC disconnector is specially designed to meet the high performance requirements of current outdoor distribution systems. Cleverly designed, it is able to withstand higher load current and fault current.

The insulator of this disconnecting switch is made of imported alicyclic materials and it features hydrophobicity, self-cleaning, UV resistance, weather resistance, and corrosion resistance.

The moving contact adopts high density silver coating. Its double-deck, cold-drawn copper blade with round edge ensures reliable connection with the fixed contact during closing. The tongue-like fixed contact is different from the moving contact in shape structure, which can prevent wear and damage. Also, the contacts will not melt or burn due to overcurrent-induced overheating. Even after prolonged exposure to polluted air, the contacts are still able to withstand rated load current without causing difficulties in switching operations.

Our high voltage AC disconnector can serve as a low-cost load switch. When used in conjunction with load breaking devices, this product can maximize its versatility and economy in the on-load operation of a distribution system. Moreover, the line can be broken at multiple points without equipping each switching device with an arc chute. No external arc will be produced and the contacts will not be burned out, thus saving costs.

Related Names

Power Disconnect Switch | 3 Phase Isolator Switch | Vertical Break Switch

Links:https://globefindpro.com/products/81913.html

-

Solar Bug Zapper (Bulletin Board Style)

Solar Bug Zapper (Bulletin Board Style)

-

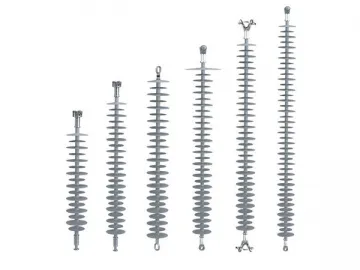

Suspension Composite Insulator

Suspension Composite Insulator

-

RY1-C Series Surge Protection Device (SPD)

RY1-C Series Surge Protection Device (SPD)

-

Composite Post Insulator

Composite Post Insulator

-

Y5W, Y10W Series Porcelain Surge Arrester

Y5W, Y10W Series Porcelain Surge Arrester

-

LED Flashlight

LED Flashlight

-

Solar Bug Zapper (Portable Style)

Solar Bug Zapper (Portable Style)

-

Y5C, Y10C Series Porcelain Lightning Arrester

Y5C, Y10C Series Porcelain Lightning Arrester

-

GW13 Outdoor High Voltage AC Neutral Point Disconnector

GW13 Outdoor High Voltage AC Neutral Point Disconnector

-

(H)GW1 Outdoor High Voltage AC Disconnector

(H)GW1 Outdoor High Voltage AC Disconnector

-

Zinc-Oxide Varistor

Zinc-Oxide Varistor

-

Polymer Line Post Insulator

Polymer Line Post Insulator