Sanitary Butterfly Valve

The stainless steel sanitary butterfly valve is usually automatic or manual. It is widely used in various industries, such as beer, dairy, beverage, pharmacy, biotechnology, etc.

Advantages

1. Imported seal: A. Received FDA hygienic certification; B. Resist acid, alkali and high temperature; C. Low compression set

2. Precisely Forged valve plug: Maximum pressure≤1.2MPa; Better metallographic structure than cast ones

3. Appearance: Latest style in the world

4. Service life: Valve: As long as that of imported valves

Seal: 18-month warranty under normal circumstances

5. Price/performance ratio: Alternative to imported valve, cost saving, reliable operation

Materials of Sanitary Butterfly Valve

1. Contact surface between the product and medium: 304 or 316L

2. Seal: Standard: EPDM

Optional: Silicon, FDM or HNBR

Types of Connecting Pipes or Equipment

1. Weld, thread, clamp, stud weld or flange

2. Conform to DN11850, IDF/ISO and SMS international standards, so as to be applied in conjunction with any imported equipment

Handle

1. Standard: Metal handle or reinforced nylon handle

2. Optional: Adjustable handle; Customization

Pneumatic actuator

1. NO, spring to open and air to close

2. NC, spring to close and air to open

3. Optional inductive probe with ON/OFF signal feedback

4. Compact design, small size and high torsion

5. Easy installation

Technical Parameters of Sanitary Butterfly Valve

1. Outside diameter range: DN25~DN200 1"~4"

2. Pressure tolerance: 10bar

3. Compressed air supply: Minimum: 4bar

Maximum: 8bar

4. Pneumatic actuator torque: 40Nm

5. Surface finish: Cutting: Ra1.6~3.2 mm

Polishing: Ra0.4~0.8 mm

Requirements for Compressed Air Quality The Actuator Needs

1. Compressed air connection:Air tube equipped with air hose coupling R1/8"

2. Maximum particle size: 0.01mm

3. Maximum oil content:0.08ppm

4. Dew point: ≤-10℃

5. Maximum water content: 7.5g/kg

Related Names

Isolating Valve Supplier | Piping Product | Flow Regulating Tool

Links:https://globefindpro.com/products/82605.html

-

Small Compressed Air Filter (1.6~23m³/min)

Small Compressed Air Filter (1.6~23m³/min)

-

Combined Air Dryer

Combined Air Dryer

-

Large Capacity Refrigerated Dryer

Large Capacity Refrigerated Dryer

-

R4105ZD 56KW Four Cylinder Diesel Engine

R4105ZD 56KW Four Cylinder Diesel Engine

-

Cummins Powered Diesel Generator Set

Cummins Powered Diesel Generator Set

-

Ecopure Series Compressed Air Filter

Ecopure Series Compressed Air Filter

-

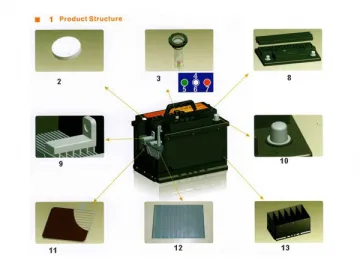

Car Battery

Car Battery

-

KDH Series High Inlet Temperature Refrigerated Dryer with Plate Heat Exchanger

KDH Series High Inlet Temperature Refrigerated Dryer with Plate Heat Exchanger

-

Heated Regenerative Desiccant Air Dryer

Heated Regenerative Desiccant Air Dryer

-

Low Temperature Refrigerated Dryer

Low Temperature Refrigerated Dryer

-

High Pressure Refrigerated Dryer

High Pressure Refrigerated Dryer

-

K4100P Constant Speed Diesel Engine

K4100P Constant Speed Diesel Engine