Heated Regenerative Desiccant Air Dryer

The KXR series heated regenerative desiccant dryer is designed with an external electric heater to heat the dried compressed air that is utilized for desiccant regeneration. The heated air shows better moisture absorption effect when it meets activated alumina, and this process only requires 6% of dried compressed air, much less than that of heatless desiccant dryers.

The heated desiccant compressed air dryer offers outlet pressure dew point of -40℃, and air flow capacity from 0.7 m3/min to 510m3/min.

Features

1. Famous Brand PLC Controller

This heated regenerative desiccant dryer takes advantage of Siemens S7200 or S7300 PLC controller to realize all the functions, and also adopts the 7" touch screen to display the working status.

2. Low Power Heater with High Temperature Interlock

The compressed air treatment equipment is available with an energy efficient external heater for efficient regeneration. The heater is protected by an incoloy alloy sheath, and comes with an interlock alarm function to provide continuous monitoring of heater sheath temperature. It will be powered off if the temperature is too high.

3. High Performance Desiccant

Desiccant in two towers is of great importance for the drying result, and we use high quality activated alumina to offer perfect performance.

4. Pressure Gauges

The same as many of our other regenerative dryers, this heated regenerative desiccant dryer is also designed with stainless steel pressure gauges installed on the two towers. Thus, users are allowed to see the pressure level clearly during working process.

5. High Performance Pneumatic Valves

The oil-less pneumatic valves are especially designed to fit for high temperature applications, and these valves have stainless steel internals as well as PTFE seats.

6. Particulate Filter

The particulate filter guarantees the safety of downstream equipment by capturing the fine desiccant particles.

7. ASME Certificated Pressure Vessels (Optional)

This range of regenerative desiccant air dryer is available with optional pressure vessels which meet the requirements of ASME Section VIII, Div. 1.

8. Mounted Pre-filter and After-filter (Optional)

For some models of the heated regenerative desiccant dryer, pre-filter and after-filter are provided to offer better drying results.

9. Tower Insulation (Optional)

The tower insulation is available on customer’s request, and it achieves enhanced regeneration efficiency. Moreover, the contact barrier realizes safe running.

10. Dew Point Display (Optional)

This adsorption dryer uses a high precision ceramic sensor to detect the dew point, and relevant data are showed on the display. In addition, high dew point alarming function is also realized.

11. NEMA 4 Rated Electrical Enclosure (Optional)

The optional electrical enclosure for the heated regenerative desiccant dryer is designed and produced according to NEMA 4 and IP66 standards. It serves to protect electrical components from falling and prevents external condensation.

Operating Conditions

| Normal Inlet Pressure | 7 bar (g) |

| Normal Inlet Temperature | 38℃ |

| Pressure Dew Point | -40℃ |

| Max. Operating Pressure | 10 bar |

| Min. Operating Pressure | 4 bar |

| Max. Inlet Temperature | 50℃ |

| Min. Inlet Temperature | 10℃ |

| Standard Power Supply | 380V/3Ph/50Hz |

Specifications

| Model | Flow Capacity | Heater (kW) | Dimensions | Air Connection | Weight | |||

| m3/min | CFM | L (mm) | W (mm) | H (mm) | (BSP) | (kg) | ||

| KXR-5 | 0.7 | 25 | 0.9 | 690 | 500 | 915 | 1/2" | 120 |

| KXR-10 | 1.6 | 56 | 0.9 | 690 | 500 | 1298 | 1" | 190 |

| KXR-20 | 2.6 | 92 | 1.5 | 780 | 500 | 1324 | 1" | 280 |

| KXR-30 | 3.8 | 134 | 1.5 | 860 | 540 | 1350 | 1" | 320 |

| KXR-60 | 7.0 | 247 | 2.4 | 1010 | 700 | 1558 | 1 1/2" | 480 |

| KXR-75 | 8.5 | 300 | 2.4 | 1010 | 700 | 1785 | 1 1/2" | 540 |

| KXR-100 | 11.5 | 406 | 4.5 | 1240 | 800 | 2232 | 2" | 650 |

| KXR-120 | 13 | 476 | 4.5 | 1240 | 800 | 2232 | 2" | 690 |

| KXR-150 | 17 | 600 | 5.4 | 1280 | 860 | 2360 | DN65 | 780 |

| KXR-200 | 23 | 812 | 7.5 | 1320 | 860 | 2477 | DN65 | 920 |

| KXR-250 | 27 | 953 | 9 | 1700 | 930 | 2570 | DN65 | 1050 |

| KXR-300 | 34 | 1200 | 10.8 | 1750 | 960 | 2626 | DN80 | 1200 |

| KXR-400 | 45 | 1588 | 15 | 1850 | 1060 | 2646 | DN100 | 1530 |

| KXR-500 | 55 | 1941 | 18 | 1850 | 1060 | 2646 | DN100 | 1750 |

| KXR-600 | 65 | 2294 | 22.5 | 2160 | 1240 | 2784 | DN125 | 2230 |

| KXR-800 | 87 | 3071 | 28.8 | 2416 | 1440 | 2827 | DN150 | 2710 |

| KXR-1000 | 110 | 3883 | 37.5 | 2980 | 2120 | 2990 | DN150 | 4130 |

| KXR-1200 | 130 | 4589 | 45 | 3080 | 2220 | 3030 | DN150 | 4700 |

| KXR-1500 | 160 | 5648 | 56 | 3180 | 2320 | 3316 | DN200 | 5800 |

| KXR-2000 | 210 | 7413 | 72 | 3380 | 2520 | 3360 | DN200 | 7370 |

| KXR-2500 | 260 | 9178 | 90 | 3580 | 2720 | 3596 | DN250 | 9020 |

| KXR-3000 | 320 | 10943 | 112.5 | 3580 | 2970 | 3606 | DN250 | 11900 |

| KXR-3500 | 360 | 12708 | 124.8 | 3720 | 3220 | 3720 | DN300 | 13100 |

| KXR-4000 | 410 | 14473 | 145.8 | 3910 | 3370 | 3910 | DN300 | 14800 |

| KXR-5000 | 510 | 18003 | 170 | 4200 | 3600 | 4200 | DN350 | 16000 |

Note: The flow capacity is based on the following conditions: Air FAD 20℃/1 bar (a), pressure 7 bar (g), relative humidity 100%, air inlet temperature 35℃, pressure dew point -40℃.

Links:https://globefindpro.com/products/82602.html

-

KDH Series High Inlet Temperature Refrigerated Dryer with Plate Heat Exchanger

KDH Series High Inlet Temperature Refrigerated Dryer with Plate Heat Exchanger

-

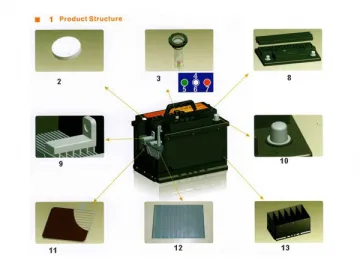

Car Battery

Car Battery

-

Sanitary Butterfly Valve

Sanitary Butterfly Valve

-

Small Compressed Air Filter (1.6~23m³/min)

Small Compressed Air Filter (1.6~23m³/min)

-

Combined Air Dryer

Combined Air Dryer

-

Large Capacity Refrigerated Dryer

Large Capacity Refrigerated Dryer

-

Low Temperature Refrigerated Dryer

Low Temperature Refrigerated Dryer

-

High Pressure Refrigerated Dryer

High Pressure Refrigerated Dryer

-

K4100P Constant Speed Diesel Engine

K4100P Constant Speed Diesel Engine

-

R6105IZLD 132KW Direct Injection Diesel Engine

R6105IZLD 132KW Direct Injection Diesel Engine

-

R6105AZLD 110KW Six Cylinder Diesel Engine

R6105AZLD 110KW Six Cylinder Diesel Engine

-

R6105ZP Constant Speed Diesel Engine

R6105ZP Constant Speed Diesel Engine