Concrete Pouring System

The concrete pouring system works for batching process, and it realizes automatic control from raw material grinding stage to slurry pouring stage. The control system is made in China, and it features reliable running, stable pouring quality as well as convenient adjustment. Hence, both the quality of AAC block and the utilization rate of equipment are improved.

Work Flow

1. First, cement, lime and gypsum in three separated silos are transported by screw conveyor to weighing hopper to measure their weights, and the weighing hopper is for dry materials. The proportion of these ingredients can be adjusted by semi-automatic control system or fully automatic PLC control system.

2. Then, fly ash or sand slurry is directly transferred to slurry weighing tank through pipelines, and the weighing process also contains semi-automatic type and fully automatic type.

3. After weighing process is completely finished, the screw conveyor is used to carry these materials into mixing tank to receive mixing treatment. At the same time, aluminum powder is manually weighed and added.

Construction Features

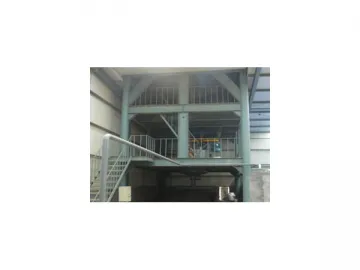

The concrete pouring system includes two kinds of structures, which are reinforced concrete structure and steel welding structure. But, the load bearing capacity must be over 200 tons no matter what kind of structure it is, and extra load bearing facilities must be applied if the raw material silos are enlarged.

Compositions

1. A three-storey frame for concrete pouring system

2. One cement silo

3. One lime silo

4. One gypsum silo

5. Weighing hopper for cement, lime and gypsum

6. Slurry weighing tank

7. Screw conveyor

8. Mixing machine

Related Names

Concrete Patio | Concrete Slab Making Unit | Concrete Mixing Tool

Links:https://globefindpro.com/products/83065.html

-

KTR500

KTR500

-

Jaw Crusher

Jaw Crusher

-

QT5-25 Automatic Block Making Machine

QT5-25 Automatic Block Making Machine

-

Kastar777 Fireproof PU Foam

Kastar777 Fireproof PU Foam

-

Concrete Batching Machine

Concrete Batching Machine

-

Plate Link Conveyor

Plate Link Conveyor

-

Plate Conveyor System

Plate Conveyor System

-

Two Part Silicone Sealant for Glass

Two Part Silicone Sealant for Glass

-

Stationary AAC Block Cutting Machine

Stationary AAC Block Cutting Machine

-

Vertical Centrifugal Slurry Pump

Vertical Centrifugal Slurry Pump

-

QT8-25 Automatic Concrete Block Machine

QT8-25 Automatic Concrete Block Machine

-

KASTER 736

KASTER 736