Deflocculants

The deflocculant is developed especially for solving the problem of difficult dispergation caused by using soil aggregate with high viscosity and water with high hardness in the ceramic slurry production process. Meanwhile, it is in compliance with the more and more high demand for energy conservation and exhaust reduction. The content of the sodium oxide in the product is more than 30%, which can decrease the viscosity of the ceramic slurry, enhance the fluidity as well as reduce the water content of the ceramic slurry and save energy effectively.

| Na2O | ≥ 30% |

| PH Value | 8-10 |

| Water Insoluble | ≤ 1% |

| Water Content | 30-34% (Free Water and Crystal Water) |

As a specialized deflocculants manufacturer and supplier in China, our company also provides matt printing glaze powder, paper faced gypsum partition board, inkjet printing frit, and rock glaze, among others.

Related Names:

Dispergator | Dispergation Agent

Links:https://globefindpro.com/products/84600.html

-

Inclusion Pigment

Inclusion Pigment

-

Melamine Faced Board

Melamine Faced Board

-

Crystal Polished Glaze for Floor Tile

Crystal Polished Glaze for Floor Tile

-

PVC Plaster Ceiling Panel

PVC Plaster Ceiling Panel

-

CMC (Sodium Salt of Carboxymethyl Cellulose)

CMC (Sodium Salt of Carboxymethyl Cellulose)

-

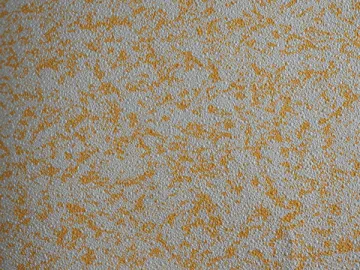

Printing Glaze for Rotocolor

Printing Glaze for Rotocolor

-

Water Glass (Sodium Silicate)

Water Glass (Sodium Silicate)

-

Matt Frit for Ceramic Tile

Matt Frit for Ceramic Tile

-

Pigment for Printing Roller

Pigment for Printing Roller

-

UV Board

UV Board

-

Waterproof Ceramic Frit

Waterproof Ceramic Frit

-

Luster Ceramic Frit

Luster Ceramic Frit