650-type Steel Coil Slitting Line

| Decoiler | Discharging trolley | The bridge after slitter | Rotary type straight arm |

This 650-type steel coil slitting line features low investment but high benefits. It is often selected by those customers who own high yearly output of machined plates with the width from 80mm to 650mm. So far, our company has produced 3 sets of this product. We build cooperative relationships with Taiwan Chunyuan Company and Shandong Xiaochuang Sheet Metal Processing Co., Ltd. All these sets have gone into operation without a hitch. The quality and stability of our product is highly praised by our clientele.

Uses

1. The 650-type steel coil slitting line is able to precisely cut the metal plates with the thickness from 0.2mm to 2.3mm. The maximum width of the plate to be cut is 650mm, and the maximum weight of coil is 8 tons.

2. Our product is appropriate for the processing of copper sheets, aluminum sheets, stainless steel sheets, color-coated sheets, cold-rolled sheets, electrolytic galvanized sheets, and the hot-dip galvanized sheets, among others.

Characteristics

1. Appearance

This 650-type steel coil slitting line is small, exquisite and beautiful. Its process layout is reasonable.

2. Efficient Operation

a. The maximum speed is 150m/min. However, a custom-made product can be designed with the speed of 200m/min. In addition, the width tolerance is ±0.05mm, and the thickness of burrs is one thirtieth of that of the plate. The maximum quantity of the slit strips is 30, and the minimum width of the slit strips is 8mm.

b. Based on the processing requirements, the coil preparation station can be added with the anti-tilt equipment, and the seamless winding technology can be adopted.

c. The tension control system takes advantage of the wool felt. It can be also assembled with the RB21 series or BB series belt tensioner imported from Japan.

d. Two slitting machines can be mounted to greatly improve the processing efficiency of the equipment.

e. Double knife holder can be configured, accompanied with the on-line production and the off-line knife positioning system. Thus, the time for positioning knives can be reduced.

3. Superb Performance of Human-Machine Interface

The touch screen enables the user to finish such operations as the fault warning, operating conditions, fault diagnosis, as well as the setting, modifying and commissioning of technical parameters.

Moreover, a perfect warning system is built in the 650-type steel coil slitting line. When the equipment failure occurs, the touch screen will display the historical alarm information and real-time alarm information. At the top right corner of the touch screen, the warning indicator will be activated by the system. Meanwhile, the sound-light warning light will start to work. In this way, the smooth operation of our equipment can be well guaranteed.

4. Automation Capability

Automation capabilities include the fixed-length cutting, fixed-weight cutting, as well as the automatic matching of the main drive speed.

5. Quality

Due to the adoption of high-precision processing equipment and high-quality components, the 650-type steel coil slitting line gives low failure rate and super high durability. Additionally, the time and cost for maintenance can be enormously saved.

Technical Specifications

| Raw Materials | Materials | Cold-rolled sheets, electrolytic galvanized sheets, hot-dip galvanized sheets, pre-painted steel sheets, stainless steel sheets, aluminum sheets, copper sheets, etc |

| Max. Weight of Coil | 8 tons | |

| Width of Steel Coil | 80~650mm | |

| Thickness of Steel Coil | 0.2~2.3mm | |

| Internal Diameter of Steel Coil | φ508mm/φ610mm | |

| External Diameter of Steel Coil | φ600mm~1600mm | |

| Processing Capability | 2.0 mm wide | 5pcs |

| 1.6 mm wide | 10pcs | |

| 0.5mm wide | 30pcs | |

| Machine Capacity | Max. Speed | 150m/min (Customizable, Maximum: 200m /min) |

| Threading Speed | 15m/min | |

| Width Tolerance | ±0.05mm | |

| Burr | ≤1/30 thickness of plate (in relation to blade clearance and blade point) | |

| Snake Shape | 0.8mm/2m | |

| Edge Misalignment of Coil | ≤0.4mm | |

| Coil Cone | ≤1.8mm | |

| Automated Capacity | Fixed-Length Cutting | 1. The cutting length can be automatically calculated. 2. Real-time shutdown |

| Fixed-Weight Cutting | 1. The weight of the finished coil can be automatically calculated. 2. Real-time shutdown | |

| Automatic Matching of Speed | Synchronous speed during production |

We can accord with the needs of our clients to customize this small-sized 650-type steel coil slitting line.

Process Flow Diagram of 650-type Steel Coil Slitting LineRelated Names

Metal Strip Slitting Machine | Galvanized Steel Coil Slitter | Thin Metal Slitting Equipment

Links:https://globefindpro.com/products/85878.html

-

Film Faced Plywood

Film Faced Plywood

-

300W Power Ribbon Wirewound Resistors

300W Power Ribbon Wirewound Resistors

-

YZPST Schottky Diode

YZPST Schottky Diode

-

Painted Aluminum Coil

Painted Aluminum Coil

-

Brushed Aluminum Composite Panel

Brushed Aluminum Composite Panel

-

Veneered MDF

Veneered MDF

-

Aluminum Composite Panel for Signage

Aluminum Composite Panel for Signage

-

PE Coated Aluminum Coil (Polyester Coating)

PE Coated Aluminum Coil (Polyester Coating)

-

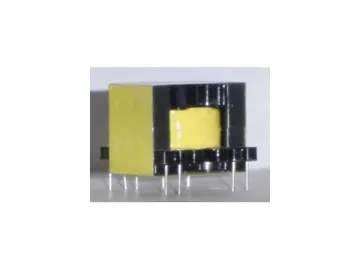

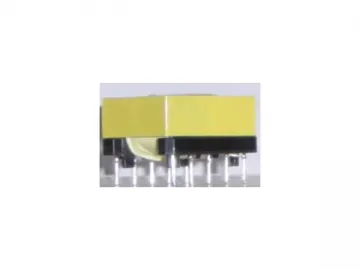

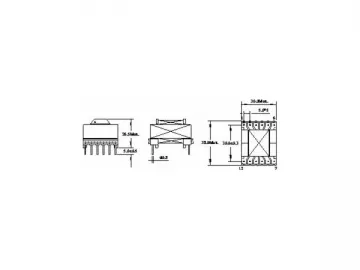

PQ Series Switch Mode Power Transformer

PQ Series Switch Mode Power Transformer

-

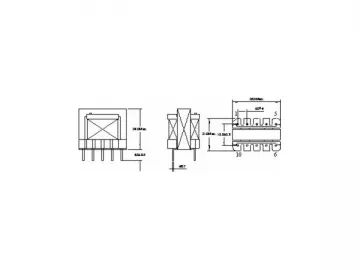

EI Series Ballast Choke

EI Series Ballast Choke

-

EFD Series Ballast Choke

EFD Series Ballast Choke

-

ER Series Switch Mode Power Transformer

ER Series Switch Mode Power Transformer