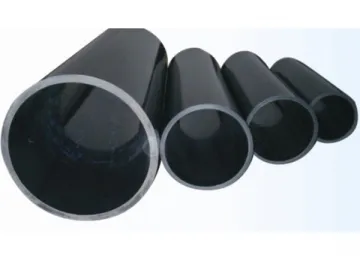

UHMW-PE Wear Resistant Pipe Extrusion Line

UHMW-PE Wear Resistant Pipe Extrusion Line

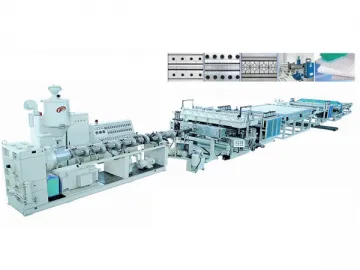

UHMW-PE wear resistant pipe extrusion line is mainly characterized by high efficiency and energy saving. It can help customers save 40% to 60% on electric power by adoption of the electromagnetic heating technique. All the electrical components like frequency converter, circuit breaker, motor, intermediate relay and others come from those world famous brands, such as Siemens, Omron, Schneider etc. This kind of electrical components can maintain the stable operation of equipment. To make easy operation and improve the production efficiency, our product also adopts PLC control that is connected with both traction unit and cutting machine.

Main Specifications

Model | Range | Extruder Model | Extrusion Speed (m/min) | Max. Output | Total Installed | Dimension L×W×H |

FUHPE-63 | 20-63 | FSJ-90X30 | 0.05-0.2 | 20 | 45 | 26×2.2×2.5 |

FUHPE-160 | 63-160 | FSJ-90X30 | 0.05-0.2 | 20 | 90 | 40×2.2×2.8 |

FUHPE-250 | 75-250 | FSJ-120X30 | 0.05-0.2 | 40 | 120 | 40×2.2×3.0 |

FUHPE-400 | 160-400 | FSJ-150X30 | 0.05-0.2 | 50 | 160 | 40×2.2×3.0 |

FUHPE-630 | 355-630 | FSJ-200X30 | 0.05-0.2 | 90 | 200 | 45×2.3×3.5 |

FUHPE-800 | 400-800 | FSJ-220X30 | 0.05-0.1 | 120 | 250 | 50×2.5×4.0 |

This wear resistant pipe extrusion line is equipped with vacuum cooling water tank. To improve the cooling effect, this tank contains two vacuum chambers. The vacuum sizing sleeve is made of brass, which has wonderful thermal conductivity. When the ultra high molecular weight polyethylene pipe passes through the sizing sleeve, this PE pipe can be cooled and calibrated quickly. Both screw and screw barrel utilizes the number 38 alloy steel, on the surface of which are treated by nitriding and quenching. The thickness ranges from 0.4 to 0.7mm, and their hardness reaches over 940.

Links:https://globefindpro.com/products/87146.html

-

Plastic Milling Machine

Plastic Milling Machine

-

Waterproof Wide Floor Sheet Extrusion Machine

Waterproof Wide Floor Sheet Extrusion Machine

-

PE/PP Plastic Film Recycling Pelletizing Machine

PE/PP Plastic Film Recycling Pelletizing Machine

-

WPC Profile Extrusion Line

WPC Profile Extrusion Line

-

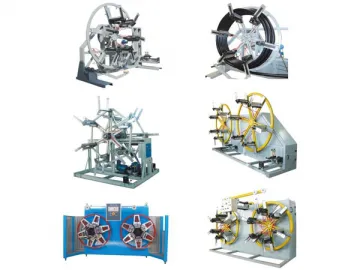

Plastic Pipe Winding Machine

Plastic Pipe Winding Machine

-

PC Plastic Hollow Grid Sheet / Board Extrusion Line

PC Plastic Hollow Grid Sheet / Board Extrusion Line

-

Single and Multilayer Plastic Mould for PVC/PE/PP Pipe

Single and Multilayer Plastic Mould for PVC/PE/PP Pipe

-

PMMA Pipe and Rod Extrusion Machine

PMMA Pipe and Rod Extrusion Machine

-

Plastic Mixer

Plastic Mixer

-

PVC Transparent Hose & Braided Fiber Reinforced Hose Extrusion Machine

PVC Transparent Hose & Braided Fiber Reinforced Hose Extrusion Machine

-

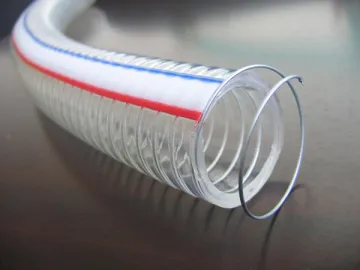

PVC Spiral Steel Wire Reinforced Hose Making Machine

PVC Spiral Steel Wire Reinforced Hose Making Machine

-

PE/PP Sheet Extrusion Machine

PE/PP Sheet Extrusion Machine