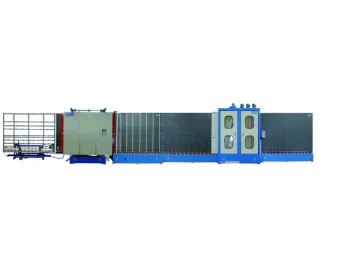

2200 Insulating Glass Production Line

LBZ2200PC Vertical Insulating glass flat press production line

LBZ2200PC Vertical Insulating glass flat press production line is applicable to the production of insulatingglass unit with aluminum spacer. This production line is composed of the feedconveyer, washing and drying station, output conveyer, aluminum frameassembling machine, assembly and press robot, and titling table. Our insulatingglass production line can realize automatic convey, washing and drying ofglass, mounting of aluminum frame, as well as automatically assemble, press,flat lay and output the insulating glass unit. This insulating glass productionline adopts the world's latest design concepts and advanced processingtechnology. It is environmentally friendly, energy-saving, highly efficient,cost-effective, and features powerful function, easy operation, low powerconsumption, convenient maintenance, etc. Due to these advantages, ourinsulating glass production line is preferred by large-scale insulating glassmanufactures.

Technical features

1) The insulating glass production line adopts full programmable logiccontroller (PLC) control system, which ensures high degree of automation andwhole user-friendly operation.

2) It has both manual and automatic control mode for option, and eachsegment of the insulating glass production line can be individually controlledwith ease.

3) The touch screen can displaythe status of work, and timely and accurately determine the operatingconditions of the equipment.

4) This insulating glass production line has automatic identificationof coated glass and low-e glass, and uses soft brushes for cleaning of ordinary glass andon-line Low-E glass.

5) Operating in anenergy-efficient way, it starts automatically when there are glasses waitingfor dealing with and shuts down when glasses are removed.

6) The insulating glassproduction line adopts folding and detachable structure for convenientinstallation and easy transportation.

7) It is suitable for producingstandard double IGU, triple IGU, Shaped IGU and optional stepped insulatingglass unit

8) The machine body of thewashing and drying station is made of stainless steel, and the transportmechanism using waterproof bearings and flexible devices can convey 3-12mm glass with no need to adjust.

9) The independent nozzle withfree-to-adjust angle and fixed retainer spring features fanwise sputtering, andcan be easily disassembled for cleaning.

10) Thedrying section and glass outlet of the insulating glass production line areequipped with thickened sound-absorbing cotton to reduce noise, and the use ofauxiliary security door can well prevent the glass from falling down and breaking.

11) Theall stainless steel air knife insulating glass production line is formed bylaser cutting and CNC bending at a time, and has even knife edge, high airpressure, low noise, and long service life.

12) Theair blower adopting circulating air heating method has good drying effects.

13) Thelateral and under positioning of aluminum frame can be manually controlled. Thepositioning block of aluminum frame adopts the buffer structure of compressedspring and rubber block, and can be freely adjusted according to the thicknessof the glass.

14) Thepressing robot of the insulating glass production line is welded by thickenedsteel frame with high strength, small deformation, and good stability.

15) The30mm high-strength inner plateis connected and fixed to the steel frame, and is especially equipped with anadvanced adjustable mechanism, ensuring constant flatness of plate and uniformand accurate assembly of insulating glass.

16) Servohandspike usescylinder and servo electric handspike. When the insulating glass productionline makes normal insulating glass, the cylinder works, and when the machinemaking stepped unit, both the cylinder and electric handspike work. This greatly improves working efficiency andlowers failure rate.

17) Thetransport back plate using high-intensity spray polymerization board isbeautiful, smooth, anti-aging, and anti-corrosive.

18) heback wheel of the insulating glass production line adopts shaft sleevestructure, and the outer layer is made of polyurethane, so that the back rollerhas good wear resistance, produces no scratch on the glass, and features smoothtransmission and low noise.

19) Thetransport roller adopts polyurethane materials and the shaft core with screwconnection avoids off-axis, which ensures good wear resistance, durableoperation, and long service life.

20) Theinsulating glass production line also uses the automatic expansion clamp canrealize stable and reliable convey of glass. By the way, all the distributionwires adopt special high-strength protection tubes for safety.

Technical Parameters of the InsulatingGlass Production Line

Water supply: 0.5T/hPH=7±1 (conductivity: ≤40μs)

Power supply: Three phase and four wire 380V/50 Hz

Air supply: Displacement0.80m/min, rated pressure 1.0MPa, motor power≥7.5KW

Total power: 30.25KW

Washing speed: 2~10 m/min

Maximum working speed: 48m/min

Production cycle: 23~30s(1000mm×1000mm)

No sealant output:1000~1200pcs /8h

Glass processing dimension:

Min: 450mm×280 mm

Max: 2200mm×3000mm

Washing glass thickness:3~12mm standard

Max. insulating glass thickness: 40mm standard (60mmoptional)

Stepped IG dimension:150mm×50mm

Transport roller height: 520mm

Transport roller spacing:184mm

Transport rollerdiameter: 57mm

Aluminum spacer width: 4~27mm

Tilting table height: 850mm

Angle of inclination:84°

Overall dimension: 18820mm×2500mm×3300mm(L×W×H)

Total weight: ≈6500kg

Key components of the Insulating Glass Production Line

| NO. | Name | Original Place | Quantity | Brand |

| 1 | PLC | Japan | 1 | Omron |

| 2 | Touch screen | Taiwan | 1 | Eview |

| 3 | Servo motor | Germany | 2 | KINCO |

| 4 | Inverter | Japan | 5 | Omron |

| 5 | Low-voltage apparatus | France | 4 | Schneider |

| 6 | Proximity switch | Switzerland | 1 | CARLO |

| 7 | Photoelectric switch | Germany | 7 | SICK |

| 8 | Microswitch | Taiwan | 4 | TEND |

| 9 | Hydraulic component | Taiwan | 2 | KOMPASS |

| 10 | Ball screw pair | Taiwan | 2 | ABBA |

| 11 | Linear guide pair | Taiwan | 2 | HIWIN |

| 12 | Vertical gear reducer | Taiwan | 2 | Topower |

| 13 | Horizontal gear reducer | Taiwan | 4 | Topower |

| 14 | Brush motor | Mainland China | 3 |

We are a China-based insulating glass production line manufacturer. We providevarious types of products such as glass loading machine, auto sealing robot,CNC glass cutting machine and sealant spreading machine.

Links:https://globefindpro.com/products/91614.html

-

Auto Sealing Robot

Auto Sealing Robot

-

JT01B Butyl Extruder Machine

JT01B Butyl Extruder Machine

-

Desiccant Filling Machine

Desiccant Filling Machine

-

Semi-Auto Spacer Bending Machine

Semi-Auto Spacer Bending Machine

-

Vertical Glass Washing Machine

Vertical Glass Washing Machine

-

Glass Edge Deletion Machine

Glass Edge Deletion Machine

-

CNC High Precision Plasma Cutter

CNC High Precision Plasma Cutter

-

CNC Flame Cutting Machine

CNC Flame Cutting Machine

-

DC Inverter Air Source Heat Pump

DC Inverter Air Source Heat Pump

-

CNC Flame Plasma Cutter

CNC Flame Plasma Cutter

-

High Temperature Air Source Heat Pump

High Temperature Air Source Heat Pump

-

Assembling Machine

Assembling Machine