Five-layer Co-extrusion PE Food Wrap Extrusion Line with Three Shaft Winder

The PE food wrap extrusion line with three shaft winder is developed to produce the self-adhesive five-layer PE food wrap film. The main raw material is LLDPE (linear low density polyethylene) which then should be mixed with various grades of auxiliary materials for production. The extruder is needed here for extrusion process.

Features of Our Production Line

1. Equipped with automatic molds and thickness gauge that has APC (automatic power control) system, this production line features high automaticity which is conductive to improving the precision of production.

2. It is provided with the protection switch with correlative light curtain and the cutter that is controlled mechanically and electrically to ensure the safety of people during the operation.

3. This PE food wrap extrusion line comes with the most advanced three-shaft winder with the highest automaticity, touch screen and PLC control system. Apart from that, the electrostatic film winding system is optional without the need of tapes, thus saving materials as well as labor cost.

4. It possesses more functions and strengths in comparison with the similar production line that has two-shaft winder. Except automatically changing film rolls and cutting off films, it also enables automatic paper tube loading and roll discharging, coming without leftover materials. Consequently, fewer labors are used and high production efficiency is achieved.

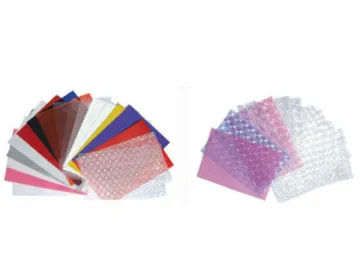

Characteristics of PE Food Wrap Film

Produced by our PE food wrap extrusion line, the PE food wrap film is self-adhesive, anti-fog, rainproof, dustproof, anti-loose, tension resistant, puncture resistant, safe, eco-friendly, sanitary, reliable, non-toxic and harmless. Conforming to GB10457-2009 Hygienic Standard for Polyethylene Products Used as Food Containers and Tableware, this film is also accordant with national quality control standards and international environmental hygiene standards.

Main Applications of PE Food Wrap Film

The PE food wrap film has widespread applications. It can be applied to the preservation of the cooked food, raw food, meats, vegetables, fruits and the seafood in homes, supermarkets, hotels, restaurants, food factories and so on.

Parameters of Our Production Line

| Model (mm) SJLM-BX-Z | 1900 | 2200 | 2500 |

| Screw Diameter (mm) | 65/100/65 | 65/110/65 | 65/125/65 |

| Length-diameter Ratio of Screw (L/D) | 32:1 | 32:1 | 32:1 |

| Width of Die (mm) | 1900 | 2200 | 2500 |

| Width of Finished Film (mm) | 1500 (300×5 rolls) | 1800 (300×6 rolls) | 2100 (300×7 rolls) |

| Thickness of Finished Film (mm) | 0.01-0.03 | 0.01-0.03 | 0.01-0.03 |

| Structure of Film | A/C/B/C/A | A/C/B/C/A | A/C/B/C/A |

| Maximum Extrusion Capacity (kg/h) | 250 | 300 | 350 |

| Linear Speed of Machine (m/minute) | 250 | 250 | 250 |

| Total Installed Power (KW) | 320 | 360 | 460 |

| Overall Dimensions (L×W×H) (m) | 15×8×6 | 15×8×6 | 16×8×6 |

| Weight (T) | 30 | 35 | 40 |

Note: The above data are subject to change without prior notice.

Links:https://globefindpro.com/products/45280.html

-

Stretch Film Slitter Rewinder

Stretch Film Slitter Rewinder

-

Triple Pass Dryer

Triple Pass Dryer

-

1200-1800mm PVC Cling Film Extrusion Line with Double Shaft Winder

1200-1800mm PVC Cling Film Extrusion Line with Double Shaft Winder

-

1800-2100mm PVC Cling Film Extrusion Line with Three Shaft Winder

1800-2100mm PVC Cling Film Extrusion Line with Three Shaft Winder

-

Double-layer/Three-layer Co-extruded Film Lamination Line

Double-layer/Three-layer Co-extruded Film Lamination Line

-

Lime Rotary Kiln

Lime Rotary Kiln

-

High Power Gear Reducer

High Power Gear Reducer

-

Waste Plastic Granulator

Waste Plastic Granulator

-

Shaft Mounted Gearbox

Shaft Mounted Gearbox

-

PE Breathable Film Extrusion Line

PE Breathable Film Extrusion Line

-

Eco-friendly 3D EVA/PU Film and Sheet Extrusion Line

Eco-friendly 3D EVA/PU Film and Sheet Extrusion Line

-

Planetary Gearbox

Planetary Gearbox