Eco-friendly 3D EVA/PU Film and Sheet Extrusion Line

The 3D EVA and PU film and sheet extrusion line is provided to professionally produce the eco-friendly EVA and PU flexible film and sheet via the advanced casting and surface molding techniques.

Features of Our Production Line

1. As the high-efficiency plasticizing screw and advanced back pressure device are adopted, the production of fish eyes on the film is effectively avoided.

2. Thanks to the sophisticated flexible calendaring and molding techniques, it can produce transparent, three-dimensional and frosted films with various colors according to different molding rollers.

3. The electrical control system of our 3D EVA and PU film and sheet extrusion line adopts the international advanced servo technology and comes with human machine interface and thereby the operation is more convenient and precise.

Characteristics of 3D EVA and PU Film and Sheet

1. Containing no plasticizer or heavy metal, the film and sheet comply with the standards of American FDA (Food and Drug Administration) and ASTM F963 as well as European ROHS (Restriction of Hazardous Substances). They are also in compliance with the current eco-friendly trend and the fine substitutes for PVC and other materials.

2. The EVA and PU films possesses the properties as flexibility, resilience, cold resistance, non-toxicity, transparency, no odor, fine adhesion and easiness for processing. They belong to remarkable eco-friendly products.

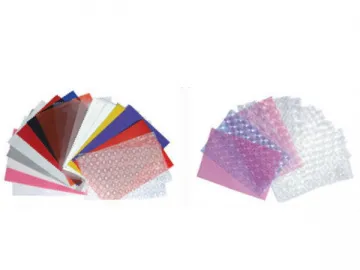

3. The film produced by our 3D EVA and PU film and sheet extrusion line comes with many styles, such as the transparent style, semi-transparent style, mirror-faced style, three-dimensional style, frosted (coarse or fine) style, etc. Besides, various colors are available.

4. The three-dimensional sheet comes with strong stereoscopic impression, gorgeous colors, fine texture and high-grade quality.

5. The PU film is a kind of top-grade eco-friendly product with extensive applications.

Main Applications of 3D EVA and PU Film and Sheet

They can be applied to hand bags, tablecloths, suitcases, shopping bags, articles for medical treatment and babies, cosmetic bags, ice bags, etc.

Parameters of Our Production Line

| Model (mm) SJLM-EVA/PU-Z | 1200 |

| Screw Diameter (mm) | 125 (multi-extruder co-extrusion) |

| Length-diameter Ratio of Screw (L/D) | 30:1 |

| Width of Finished Film (mm) | 1200 |

| Thickness of Finished Film (mm) | 0.15-0.80 |

| Maximum Extrusion Capacity (kg/h) | 250 |

| Linear Speed of Machine (m/minute) | 20 |

| Total Installed Power (KW) | 250 |

| Overall Dimensions (L×W×H) (m) | 18×5×4.5 |

| Weight (T) | 20 |

Note: The above data are subject to change without prior notice.

Links:https://globefindpro.com/products/45275.html

-

PE Breathable Film Extrusion Line

PE Breathable Film Extrusion Line

-

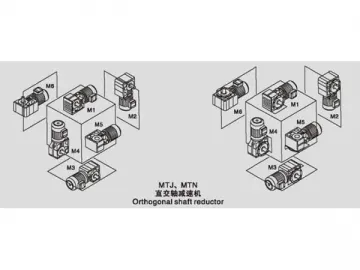

Shaft Mounted Gearbox

Shaft Mounted Gearbox

-

Waste Plastic Granulator

Waste Plastic Granulator

-

High Power Gear Reducer

High Power Gear Reducer

-

Five-layer Co-extrusion PE Food Wrap Extrusion Line with Three Shaft Winder

Five-layer Co-extrusion PE Food Wrap Extrusion Line with Three Shaft Winder

-

Stretch Film Slitter Rewinder

Stretch Film Slitter Rewinder

-

Planetary Gearbox

Planetary Gearbox

-

Single Layer /Multi-layer Co-extrusion PEVA Cast Embossed Film Line

Single Layer /Multi-layer Co-extrusion PEVA Cast Embossed Film Line

-

Helical Gearmotor

Helical Gearmotor

-

Helical Bevel Gearmotor

Helical Bevel Gearmotor

-

1500mm Three-layer Co-extruded PE Cast Stretch Film/Silage Film Line

1500mm Three-layer Co-extruded PE Cast Stretch Film/Silage Film Line

-

Stepless Speed Variator

Stepless Speed Variator