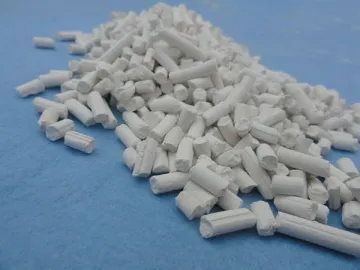

Diesel Deep Hydrotreating Catalyst

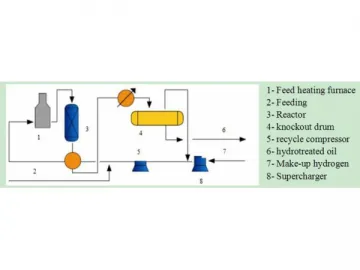

The HHMDS series diesel deep hydrotreating catalyst is a newly developed petrochemical catalytic agent with improved desulfurization activity, and it is also characterized by low bulk density, high dispersity of active metals, reasonable formula of active components, etc.

Application

1. HHMDS-1 Deep Hydrotreating Catalyst

HHMDS-1 is especially designed for the second reforming process of high sulfur diesel, and it delivers satisfying sulfur and olefin removal results, thus providing technical support for oil refineries to manufacture high quality diesel fuels using their 6.0-8.0MPa hydrotreating units at the space velocity of 1.0-2.5h-1. Moreover, the sulfur content of produced diesel oil is compliant with Euro III, Euro IV and Euro V standards.

In general, our W-Mo-Ni hydroprocessing catalyst is a perfect choice for petrochemical industry, and it is commonly adopted in deep hydrotreating process of straight-run diesel, coker diesel, mixture of coker gasoline and coker diesel, etc.

2. HHMDS-2 Deep Hydrotreating Catalyst

HHMDS-2 is aimed at inferior diesel oil with high sulfur and nitrogen contents, and it suits for deep desulfurization, denitrogenation and dearomatization. Compared with other catalysts for second reforming of high-nitrogen distillates, its reaction temperature is about 5℃ lower, and its desulfurization and denitrogenation activities are 20% higher, but their hydrofining results are the same.

This Mo-Ni catalyst is applicable for deep hydrotreating straight-run diesel, coker diesel, mixture of coker gasoline and coker diesel, etc. It also suits for pre-hydrogenation of distillates, such as FCC and hydrocracking materials.

Technical Data of Diesel Deep Hydrotreating Catalyst

| Model | HHMDS-1 | THDS-II |

| Active metal type | W-Mo-Ni | Mo-Ni |

| Active metal content (wt%) | ≤30 | About 28 |

| Shape | Quatrefoil | Trefoil |

| Diameter (mm) | Ф1.5-2.0 | Ф1.3-1.6 |

| Pore volume (ml/g) | ≥0.30 | ≥0.30 |

| Specific surface area (m2/g) | ≥200 | ≥180 |

| Bulk density (g/ml) | ≤0.75 | 0.75-0.83 |

| Crush strength (N/cm) | ≥150 | ≥150 |

Performance Case 1

| Raw oil | Mixture of straight-run diesel, catalytic diesel and coker diesel | |

| Partial pressure of H2 (MPa) | 6.18 | |

| Inlet temperature (℃) | 308 | |

| Space velocity (h-1) | 1.8 | |

| Density (kg/m3) | 861.6 (before) | 840.4 (after) |

| T95 (℃) | 363 (before) | 355 (after) |

| Sulfur content (mg/g) | 11,200 (before) | 290 (after) |

| Nitrogen content (mg/g) | 353 (before) | 44.1 (after) |

Performance Case 2

| Reaction pressure (MPa) | 4-6 | |

| Space velocity in volume (h-1) | 1.0-2.5 | |

| Reaction temperature (℃) | 250-300 | |

| H2/oil ratio in volume | 300-500 | |

| Density at 20℃ (g/ml) | 0.8087 | |

| Boiling range: IBP (℃) | 186 | |

| Boiling range: 10% (℃) | 192 | |

| Boiling range: 50% (℃) | 204 | |

| Boiling range: 90% (℃) | 224 | |

| Boiling range: EBP (℃) | 230 | |

| Sulfur content (μg/g) | 520 (before) | <5 (after) |

| Nitrogen content (μg/g) | 9.8 (before) | <1 (after) |

| Bromine content (mg/100g) | 1160 (before) | 168 (after) |

| Basic nitrogen content (μg/g) | 4.2 (before) | 0.22 (after) |

Links:https://globefindpro.com/products/76950.html

-

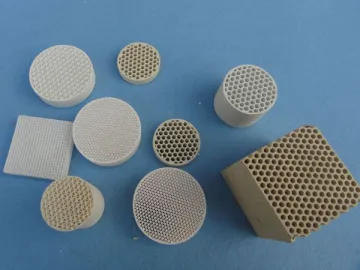

Honeycomb Ceramic Packing

Honeycomb Ceramic Packing

-

Maleic Anhydride Catalyst Carrier

Maleic Anhydride Catalyst Carrier

-

Primary Reforming Catalyst

Primary Reforming Catalyst

-

Light Distillate Hydrotreating Catalyst

Light Distillate Hydrotreating Catalyst

-

Heat Resistant Reforming Catalyst

Heat Resistant Reforming Catalyst

-

Energy Saving PET Sheet Extrusion Line

Energy Saving PET Sheet Extrusion Line

-

Exhaust Gas Purifying Catalyst

Exhaust Gas Purifying Catalyst

-

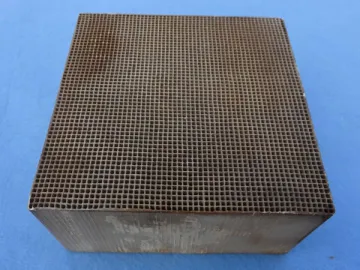

Metal Structured Packing

Metal Structured Packing

-

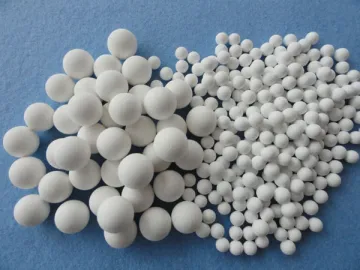

Ceramic Ball

Ceramic Ball

-

Cast Film Printing and Lamination Line

Cast Film Printing and Lamination Line

-

Desulfurization Adsorbent

Desulfurization Adsorbent

-

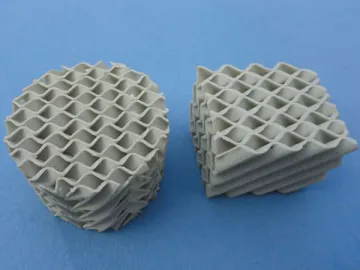

Ceramic Structured Packing

Ceramic Structured Packing