Primary Reforming Catalyst

The HHZ01 primary reforming catalyst is used in primary reformers to synthesize hydrogen or ammonia by steam or methane-containing gases, such as natural gas, refinery gas, associated petroleum gas, coke oven gas and so on.

Feature

This steam reforming catalyst takes aluminum oxide, calcium oxide, magnesium oxide and other oxides as its carrier, while nickel oxide works as the major active component, thus imparting some excellent properties, such as high mechanical strength, simple reduction and loading, good low temperature activity, good resistance to carbon forming, etc.

Conforming to HG2273.1-2004 standard, our natural gas reforming catalyst contains different models, and these catalysts differ from each other in technical performance. As a result, different catalyst combinations could be selected according to specific process flow and tube design, thereby offering optimized catalytic effect.

Technical Data of Primary Reforming Catalyst

| Active component: NiO (wt%) | ≥14.5 | |

| Active component: SiO2 (wt%) | ≤0.2 | |

| Active component: Fe2O3 (wt%) | ≤0.35 | |

| Composite carrier | CaO-MgO-La2O3-Al2O3 | |

| Remaining methane (%) | ≤10.00 | |

| Space velocity at 3.6MPa (h-1) | 2500 | |

| Service life (year) | ≥3 | |

| Appearance | Cylinder with several axial holes | Dentation with several axial holes and domed ends |

| Diameter (mm) | 14 | 17 |

| Length (mm) | 11 | 17 |

| Inner hole diameter (mm) | 4.5 | 4.5 |

| Bulk density (kg/m3) | 1000-1100 | 1000-1100 |

| Average crush strength in N (radial) | ≥250 | ≥250 |

| Percentage of catalyst with crushing strength lower than 160N | ≤5.0 | ≤5.0 |

| Specific surface area (m2/g) | 3.0-5.0 | 3.0-5.0 |

| Pressure drop in Pa (1m×Φ100 tube) | ≤2000 | ≤1500 |

Operating Condition of Primary Reforming Catalyst

| Inlet temperature (℃) | Outlet temperature (℃) | Working pressure (MPa) | Space velocity (h-1) | Water/carbon ratio | Inlet gas requirement |

| 400-650 | 650-950 | 0.7~5.0 | ≤2500 | ≥2.5 | H2S≤0.5ppm |

Links:https://globefindpro.com/products/76953.html

-

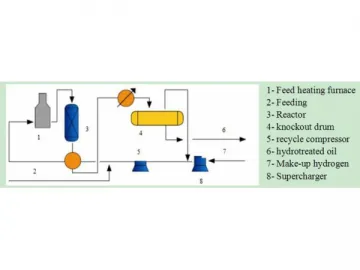

Light Distillate Hydrotreating Catalyst

Light Distillate Hydrotreating Catalyst

-

Heat Resistant Reforming Catalyst

Heat Resistant Reforming Catalyst

-

Energy Saving PET Sheet Extrusion Line

Energy Saving PET Sheet Extrusion Line

-

Molecular Sieve

Molecular Sieve

-

Activated Alumina

Activated Alumina

-

Ammonia Decomposition Catalyst

Ammonia Decomposition Catalyst

-

Maleic Anhydride Catalyst Carrier

Maleic Anhydride Catalyst Carrier

-

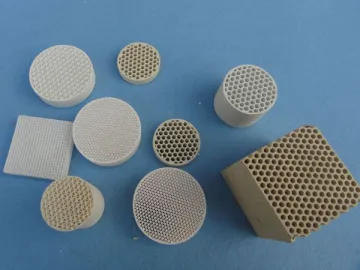

Honeycomb Ceramic Packing

Honeycomb Ceramic Packing

-

Diesel Deep Hydrotreating Catalyst

Diesel Deep Hydrotreating Catalyst

-

Exhaust Gas Purifying Catalyst

Exhaust Gas Purifying Catalyst

-

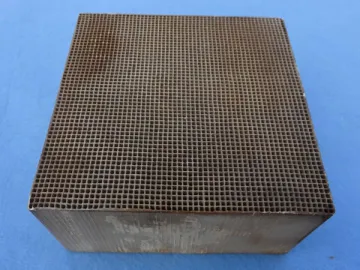

Metal Structured Packing

Metal Structured Packing

-

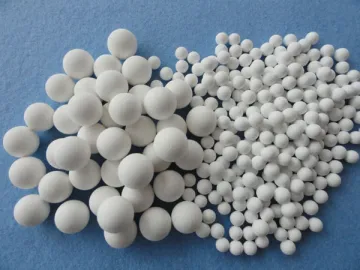

Ceramic Ball

Ceramic Ball