CNC Hydraulic Press Brake

1. WC67K series CNC hydraulic press brake has a reinforced welded steel frame which comes with good rigidity and stability due to the adoption of vibratory stress relief treatment. This ensures enhanced stability and safety during operation.

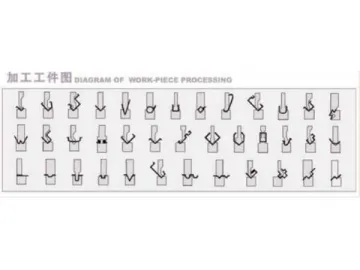

2. The hydraulic bending brake supports storage of maximum 50 processing steps at a time, thus satisfying the demand of processing complex workpieces just within one procedure, avoiding second adjustment. The one-time processing ensures ultra high accuracy.

3. There are two oil cylinders that are in charge of the vertical movement of slide. The slide is down-stroke type, and it features great reliability due to the electro-hydraulic synchronous mechanism.

4. The DA52 CNC system for the hydraulic press brake is designed on the basis of our years of experience in this field, and it functions to control the position of the backgauge and die block. The positioning accuracies are 0.1mm and 0.01mm, respectively.

5. This CNC hydraulic bending machine adopts our patented technology to realize auto switch between X axis and Y axis. The specialized one-way positioning function overcomes the lead screw gap. Along with these, screw-pitch deviation is also taken into consideration to guarantee the machining accuracy, and auto retraction function is used to avoid interference between workpiece and backgauge.

6. As illustrated above, both improved working efficiency and reduced production cost are achieved, and thus sheet metal bending machine well demonstrates the meaning of high price performance ratio.

7. Our CNC hydraulic press brake is famous for high strength, low noise, stable running as well as good shock resistance, and it can work for consecutive 16 hours under proper conditions.

Main Parts

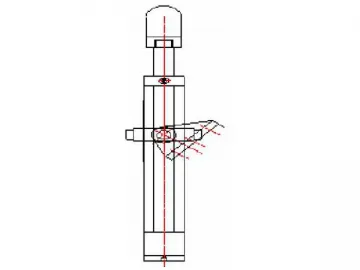

1. Slide System

The slide system for our CNC hydraulic press brake is comprised of the slide, oil cylinder and the mechanical block micro-adjustment unit. The left- and right-side oil cylinders are fixed on the machine frame, and the hydraulic system drives the slide through piston rod.

2. Synchronous System

The mechanical synchronous mechanism is made up of the torsion shaft and arm. It is characterized by simple structure, stable performance as well as high precision, and the mechanical block movement is motor-driven and controlled by the DA52 CNC system.

3. Backgauge System

This range of metal fabrication equipment adopts a suspended control station for the control of the backgauge system. The same as the slide system, the forward and backward movement of backgauge is also motor-driven and controlled by the DA52 CNC system.

4. DA52 CNC System

The CNC control system is panel-like, and can be installed in the electric cabinet or suspended cabinet. Aside from all the basic functions just like other CNC hydraulic press brakes, the unique shortcut key mode makes fast and simple programming come into being.

Detailed Information about the DA52 CNC System for Our Hydraulic Press Brake

| 1. 6.4" true color TFT LCD 2. VGA 2. User-friendly DELEM interface 3. USB port 4. RS-232 port 5. 266MHz CPU 6. Min. memory capacity: 2MB 7. Memory capacity: 64MB 8. 30 punches and 30 dies stored 9. Optoelectronic isolation, I/O port 10. Encoder (single end/differential, 5V/12V ) 11. Maximum 4 axes covering Y1, Y2 and two auxiliary axes 12. Angle programming for Y axis 13. Deflection compensation for work table 14. Pressure control 15. Shortcut key 16. One-page fast programming | 17. Advanced control algorithm for Y axis, suitable for open-loop and closed-loop 18. Memory function when power failure 19. Optional valve amplifier (Y1, Y2) 20. Servo motor or double speed motor 21. Monopole control or frequency converter 22. Proportional pressure valve for direct drive 23. Proportional direction valve integrated with VA function for direct drive 24. Max. 5-channel digital output 25. Multi-sets tandem working function 26. 7-digit program number 27. Drawing number: 20 symbols including letters and numbers 28. Max. workpiece counting: 9999 29. Max. reciprocating steps: 99 30. Programming demonstration 31. Conversion between metric system and British system32. Programmable speed for each step |

Links:https://globefindpro.com/products/82924.html

-

DIN 558

DIN 558

-

Hydraulic Tandem Press Brake

Hydraulic Tandem Press Brake

-

SS100 Material Hoist

SS100 Material Hoist

-

Plate Leveling Machine

Plate Leveling Machine

-

Hydraulic Swing Beam Shear

Hydraulic Swing Beam Shear

-

Manual Sheet Metal Folding Machine

Manual Sheet Metal Folding Machine

-

Hex Socket Head Cap Screw

Hex Socket Head Cap Screw

-

Hydraulic Press Brake

Hydraulic Press Brake

-

Adjustable 3-Roll Plate Bending Machine

Adjustable 3-Roll Plate Bending Machine

-

Hex Bolt

Hex Bolt

-

3 Roller Plate Bending Machine for Trailer

3 Roller Plate Bending Machine for Trailer

-

3-Roll Plate Bending Machine for Ship

3-Roll Plate Bending Machine for Ship