Hydraulic Press Brake

1. The WC67Y series hydraulic press brake is a commonly used metal forming machine with nominal force between 300 and 4000 kN. It has a built-in mechanical block to ensure the accurate positioning of slide. Also, it adopts a rigid torsion shaft to guarantee the synchronous movement of slides.

2. The sheet metal bending machine features motor-driven X and Y axes, and supports fully digital display to ensure convenient operation.

3. The hydraulic top drive system ensures constant stability and reliability.

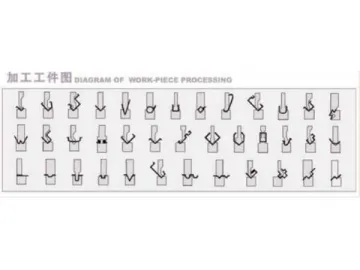

4. The sheet metal is loaded and clamped in one step, and then it is processed at a time, offering high machining precision.

5. The hydraulic press brake is constructed by steel plate via welding process, and vibrating stress relief treatment is applied to eliminate internal stress. Thus, the whole machine shows good stability, while the operation is safe and convenient. In addition, the combination of performance hydraulic system and specialized NC-89W digital display system contributes to ideal bending effects.

Product Structure

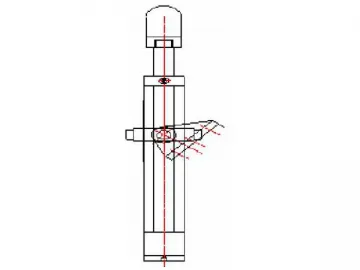

1. Slide System

The slide system of our hydraulic press brake consists of the slide, oil cylinder and the micro-adjustment unit for mechanical block. The left- and right-side oil cylinders are fixed on the frame, and they make use of the piston rod to realize the vertical movement of slides. The adjustment of mechanical block is digitally displayed by the NC-89W control system.

2. Worktable Unit

This range of hydraulic bending brake is available with a suspended control box to control the worktable unit.

An electric motor is adopted to drive the backgauge system to move forward or backward, and the NC-89W control system with minimum reading of 0.1mm acts to display the position digitally.

Additionally, our hydraulic press brake is outfitted with travel switches to further ensure backgauge positioning accuracy.

3. Synchronous System

This hydraulic plate bending machine has a mechanical synchronous system that is made up of the torsion shaft, swing arm, joint bearing, and more. Due to simple structure, the synchronous system offers reliable and precision performance. The positioning of mechanical block is adjusted by motor while the positioning data is digitally displayed by the NC-89W.

4. Backgauge System

The hydraulic press brake features a motor-driven backgauge system, and adopts a chain wheel to make two lead screws move synchronously. The NC-89W digital display system serves to show the backgauge distance. The high precision brake press also supports manual micro-adjustment of the backgauge unit.

Features of NC-89W Digital Display System

The NC-89W digital display system is available with a 128×64 LCD as well as a built-in PLC, which makes the hydraulic press brake convenient for operation.

This system is able to control the X axis and Y axis, detect switching signals, etc. Additionally, it can realize many other functions, such as auto positioning, value counting, one-way positioning, control valve group, power failure memory, and more. In addition, the digital display system adopts some state-of-the-art technologies, including man-machine conversation, unique positive and negative rotation for control motor, etc.

Technical Parameters

| Model | Nominal force (kN) | Work table length (mm) | Distance between vertical columns (mm) | Throat depth (mm) | Slide stroke(mm) | Max. Openheight (mm) | Adjustmentrange of slide stroke (mm) | Main motor power (kW) | Net weight(kg) | Overall Dimensions (L×W×H, mm) |

| WC67Y- 30/1320 | 300 | 1320 | 1140 | 200 | 80 | 320 | 60 | 3 | 2000 | 1940×1510×1905 |

| WC67Y- 30/1600 | 300 | 1600 | 1420 | 200 | 80 | 320 | 60 | 3 | 2300 | 2220×1510×1905 |

| WC67Y- 40/1320 | 400 | 1320 | 1120 | 200 | 100 | 340 | 80 | 4 | 2200 | 1950×1600×2070 |

| WC67Y- 40/1600 | 400 | 1600 | 1400 | 200 | 100 | 340 | 80 | 4 | 3300 | 2230×1600×2070 |

| WC67Y- 40/2000 | 400 | 2000 | 1800 | 200 | 100 | 340 | 80 | 4 | 3300 | 2555×1600×2070 |

| WC67Y- 40/2500 | 400 | 2500 | 2300 | 200 | 100 | 340 | 80 | 4 | 3600 | 3055×1600×2070 |

| WC67Y- 63/2500 | 630 | 2500 | 2260 | 250 | 100 | 355 | 80 | 5.5 | 4800 | 3100×1725×2355 |

| WC67Y- 63/3200 | 630 | 3200 | 2960 | 250 | 100 | 355 | 80 | 5.5 | 5600 | 3800×1725×2355 |

| WC67Y- 80/2500 | 800 | 2500 | 2240 | 250 | 100 | 355 | 80 | 7.5 | 5900 | 3100×1725×2240 |

| WC67Y- 80/3200 | 800 | 3200 | 2940 | 250 | 100 | 355 | 80 | 7.5 | 6600 | 3800×1725×2240 |

| WC67Y- 80/4000 | 800 | 4000 | 3740 | 250 | 100 | 355 | 80 | 7.5 | 7800 | 4600×1765×2400 |

| WC67Y- 100/2500 | 1000 | 2500 | 2210 | 320 | 120 | 415 | 100 | 7.5 | 7300 | 3150×1850×2530 |

| WC67Y- 100/3200 | 1000 | 3200 | 2910 | 320 | 120 | 415 | 100 | 7.5 | 8100 | 3850×1850×2690 |

| WC67Y- 100/4000 | 1000 | 4000 | 3710 | 320 | 120 | 415 | 100 | 7.5 | 9200 | 4750×1850×2800 |

| WC67Y- 125/2500 | 1250 | 2500 | 2210 | 320 | 120 | 415 | 100 | 7.5 | 7800 | 3150×1850×2530 |

| WC67Y- 125/3200 | 1250 | 3200 | 2910 | 320 | 120 | 415 | 100 | 7.5 | 8150 | 3850×1850×2690 |

| WC67Y- 125/4000 | 1250 | 4000 | 3710 | 320 | 120 | 415 | 100 | 7.5 | 9800 | 4750×1850×2800 |

| WC67Y- 160/3200 | 1600 | 3200 | 2830 | 320 | 200 | 455 | 160 | 11 | 12000 | 3900×1940×2630 |

| WC67Y- 160/4000 | 1600 | 4000 | 3630 | 320 | 200 | 455 | 160 | 11 | 14000 | 4700×1940×2800 |

| WC67Y- 160/6000 | 1600 | 6000 | 5630 | 320 | 200 | 455 | 160 | 11 | 19500 | 6700×2340×3100 |

| WC67Y- 200/3200 | 2000 | 3200 | 2800 | 320 | 200 | 455 | 160 | 15 | 15800 | 3900×2000×2970 |

| WC67Y- 200/4000 | 2000 | 4000 | 3600 | 320 | 200 | 455 | 160 | 15 | 17200 | 4900×2000×2990 |

| WC67Y- 200/6000 | 2000 | 6000 | 5600 | 320 | 200 | 455 | 160 | 15 | 24600 | 6900×2100×3700 |

| WC67Y- 250/3200 | 2500 | 3200 | 2850 | 400 | 250 | 560 | 200 | 18.5 | 19200 | 3950×2200×3100 |

| WC67Y- 250/4000 | 2500 | 4000 | 3650 | 400 | 250 | 560 | 200 | 18.5 | 21500 | 4950×2200×3300 |

| WC67Y- 250/6000 | 2500 | 6000 | 5650 | 400 | 250 | 560 | 200 | 22 | 28800 | 6950×2300×3700 |

| WC67Y- 300/3200 | 3000 | 3200 | 2720 | 400 | 250 | 560 | 200 | 22 | 22800 | 4000×2300×3500 |

| WC67Y- 300/4000 | 3000 | 4000 | 3520 | 400 | 250 | 560 | 200 | 22 | 24900 | 4800×2300×3600 |

| WC67Y- 300/6000 | 3000 | 6000 | 5520 | 400 | 250 | 560 | 200 | 30 | 32000 | 6800×2600×3800 |

| WC67Y- 400/3200 | 4000 | 3200 | 2800 | 400 | 320 | 630 | 270 | 30 | 24000 | 3800×2680×3440 |

| WC67Y- 400/4000 | 4000 | 4000 | 3600 | 400 | 320 | 630 | 270 | 30 | 30000 | 4800×2680×3540 |

Links:https://globefindpro.com/products/82922.html

-

Hex Socket Head Cap Screw

Hex Socket Head Cap Screw

-

CNC Hydraulic Press Brake

CNC Hydraulic Press Brake

-

DIN 558

DIN 558

-

Hydraulic Tandem Press Brake

Hydraulic Tandem Press Brake

-

SS100 Material Hoist

SS100 Material Hoist

-

Plate Leveling Machine

Plate Leveling Machine

-

Adjustable 3-Roll Plate Bending Machine

Adjustable 3-Roll Plate Bending Machine

-

Hex Bolt

Hex Bolt

-

3 Roller Plate Bending Machine for Trailer

3 Roller Plate Bending Machine for Trailer

-

3-Roll Plate Bending Machine for Ship

3-Roll Plate Bending Machine for Ship

-

Small and Medium-Sized 3 Roll Plate Bending Machine

Small and Medium-Sized 3 Roll Plate Bending Machine

-

5-6 Ton Tower Crane

5-6 Ton Tower Crane