3 Roller Plate Bending Machine for Trailer

The 3 roller plate bending machine is designed for roll forming and pre-bending of trailer body, parts, and tanks. It supports one-time feeding and forming of carbon steel plates, low alloy steel plates, etc. under ambient temperatures.

The hydraulic roll bender is designed drum shaped upper roll to ensure high straightness of end products. The upper roller is able to move in two directions, both vertically and horizontally. The vertical motion is hydraulic driven, and the power is obtained by the work of hydraulic oil on piston rod. The torque is transferred through worm and worm gear, worm gear box as well as lead screw, providing power for the horizontal motion.

The lower roller of the hydraulic plate bending machine only rotates and offers torque for roll forming of sheet metal, and there are adjustable support rollers under it. The nominal height of lower roller is constant, providing convenience for material feeding and operation.

This roll bending machine offers high safety and convenient system connection. Users are provided with detailed electrical schematic diagram, thus allowing them to connect wire in strict accordance with the diagram.

All the electrical appliances are supplied by famous enterprises, and electric protection devices, including current relay, air switch and others, receive severe tests before installation to guarantee reliable running. The hydraulic valve is manufactured by Yuci Yuken Hydraulics, and the ejection device is hydraulic driven with fast response speed. Additionally, the 3-roller plate bending machine features a smooth and bright painted surface which comes with uniform paint thickness.

Generally speaking, this upper roller universal plate rolling machine is characterized by stable running, flexible operation as well as high reliability, and some annoying problems are eliminated, such as oil leakage, abnormal noise, work jam, etc.

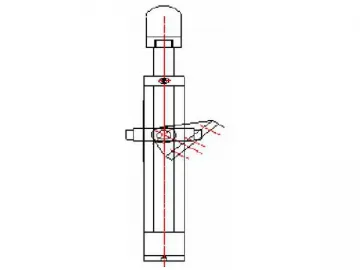

Main StructureOur hydraulic plate bending machine is comprised of the upper roller assembly, lower roller assembly, support roller assembly, main transmission device, ejection device, left and right rack, base, and the balancing device.

1. Upper Roller Assembly

The upper roller assembly for the sheet metal bending roll is composed of the main oil cylinder, bearing seat, upper roller, double row self-aligning bearing and other components. The two main oil cylinders supply pressure needed for working, and the working pressure of cylinder is 19.5MPa. The double row self-aligning bearing adopts low speed heavy duty self-aligning roller bearing, and the upper roller is made of 42CrMo and offers hardness up to HB 260-300.

2. Lower Roller Assembly and Horizontal Motion Device

The lower roller assembly includes the lower rollers, bearing seat, input gear, sliding bearing, etc. The lower roller is constructed by 45# steel, whilst the sliding bearing of lower roller adopts SF-1 self-lubricating composite material.

When it comes to the horizontal motion device, there is a relevant motor to offer power, and the horizontal movement of upper roller is achieved with the help of worm and worm gear, worm gear box and lead screw. Thus, the three roller plate bending machine is allowed to realize the asymmetric bending of metal plate.

The main transmission device offers power, and the torque is transferred to lower rollers by output gear of main transmission and input gear of lower roller. In addition, it is open gear transmission.

3. Support Roller Assembly

The main components for this part are support roller, worm and worm gear, and wedge block. The support roller is made of 45# steel, and it has two groups, 4 in one group. The support rollers are adjusted vertically according to the load for metal plate.

4. Main Transmission Device

The transmission unit for the plate bending machine includes main motor, V-belt, cylindrical gear reducer, electro-hydraulic push rod brake, etc. The output gear drives corresponding gears of two lower rollers, and the main transmission realizes positive and negative rotations to supply torque for bending process.

5. Ejection Device

The unit is mainly composed of ram and relevant oil cylinder. The piston rod of the oil cylinder is coated with chromium, and this device is designed to take out end products along the axial direction of roller.

6. Fixed, Tip-Over Racks, and Base

The 3 roller plate bending machine comes with welded base and racks with. All these parts are annealed to eliminate internal stress, thus preventing deformation even after long term continuous use.

The fixed and tip-over racks are used to set two main oil cylinders. The base adopts frame structure with high torque resistant factor, and the low number of anchor bolt facilitates installation and testing.

Hydraulic System

Our plate bending machine takes advantage of a state-of-the-art hydraulic system, which consists of hydraulic pump, valve group, auxiliary hydraulic device, adapting components for fluid, etc.

(1) Superposition valve provided by Yuci Yuken Hydraulic is adopted as the hydraulic valve.

(2) For convenient maintenance, the sheet metal rolling machine adopts the hydraulic system pipeline with simple arrangement.

(3) The hydraulic system contains three loops, including overpressure protection and pressure regulating loop, synchronous loop, and speed loop. The pressure regulating loop is designed to adjust the working pressure of this system through main overflow valve, and the working pressure is 19.5MPa.

(4) Additionally, the 3 roller plate bending machine is designed with several protection measures for the hydraulic system. For example, there are overflow valves for pressure protections for the raise and descent of upper roller.

Electrical System

This metalworking tool uses a well designed electrical system to realize efficient control, and the electrical system is mainly composed of the operation console and the handheld button box.

(1) The application of PLC reduces the number of relay, and reliable control and long life span are both obtained.

(2) On the operation console, there are control buttons and indicators for the whole machining process, and they are designed to carry out operations and monitoring.

(3) The plate rolling machine offers several protection functions to ensure safety of the electrical system. For the motor, circuit breaker is employed for overcurrent protection, while thermal relay is applied for load protection.

(4) In addition, there are upper and lower limit switches for tip-over and reset actions of ejection device. As for the total power supply, it is equipped with shunt release, and two emergent stop buttons are set on operating console and tip-over rack respectively to cut off electricity under urgent situations.

(5) To further protect operator and the three roller plate bending machine, some interlock functions are also offered. For example, only when the tip-over device completely returns to its original position, could the motion of upper roller be executed, and there is a relevant limit switch for detection. Under the condition that the upper roller moves to the top position as detected by corresponding limit switch, the individual descent of tip-over device is not allowed. In addition, when PLC breaks down, the indicator will send out alarm message for operator.

Technical Parameters

| Model | Pressure of upper roller (ton) | Max. plate thickness (mm) | Plate width (mm) | Diameter of upper roller (mm) | Diameter of lower roller (mm) | Central distance (mm) | Motor power (kW) | |||

| Plateedge | Center | Driving motor | Hydraulic motor | Motor for motion | ||||||

| W11SNC-8×6000 | 130 | 6 | 8 | 6000 | 450 | 260 | 360 | 15 | 7.5 | 4 |

| W11SNC-8×8000 | 160 | 8 | 8 | 8000 | 480 | 280 | 360 | 15 | 7.5 | 4 |

| W11SNC-8×9000 | 190 | 8 | 9 | 9000 | 520 | 290 | 370 | 17.5 | 7.5 | 4 |

| W11SNC-10×6000 | 160 | 10 | 10 | 6000 | 460 | 270 | 380 | 18.5 | 7.5 | 7.5 |

| W11SNC-16×6000 | 270 | 16 | 16 | 6000 | 520 | 320 | 440 | 30 | 11 | 7.5 |

| W11SNC-20×6000 | 320 | 20 | 20 | 6000 | 550 | 340 | 480 | 37 | 15 | 11 |

Note: The parameters are subject to change without prior notice.

Links:https://globefindpro.com/products/82918.html

-

Hex Bolt

Hex Bolt

-

Adjustable 3-Roll Plate Bending Machine

Adjustable 3-Roll Plate Bending Machine

-

Hydraulic Press Brake

Hydraulic Press Brake

-

Hex Socket Head Cap Screw

Hex Socket Head Cap Screw

-

CNC Hydraulic Press Brake

CNC Hydraulic Press Brake

-

DIN 558

DIN 558

-

3-Roll Plate Bending Machine for Ship

3-Roll Plate Bending Machine for Ship

-

Small and Medium-Sized 3 Roll Plate Bending Machine

Small and Medium-Sized 3 Roll Plate Bending Machine

-

5-6 Ton Tower Crane

5-6 Ton Tower Crane

-

Four-Roll Plate Bending Machine

Four-Roll Plate Bending Machine

-

Flat Top Tower Crane

Flat Top Tower Crane

-

SC200 Construction Hoist

SC200 Construction Hoist