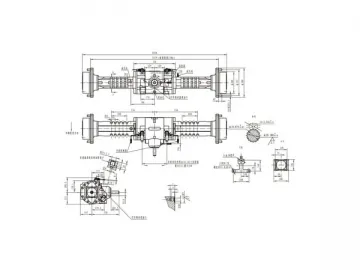

Conical Twin Screw Extruder

Our conical twin screw extruder shows a sweet plasticization design concept, which can guarantee the quality of materials. Our extremely reliable and effective design concept can also ensure the reliable extrusion process. Moreover, our extruder adopts the dedicated high-torque drive system. Both teeth and shaft are constructed from high-strength alloy steel, and they have also gone through both carburizing and tooth-grinding treatment process.

The newly developed screw can be suited for the formula which needs a great amount of infill. The feed material in this screw can possess high degree of filling, as well as the best distribution of material flow. In addition, the screw is provided with the core temperature regulating device as well as the favorable barrel-cooling system, which can realize the accurate control for the material processing temperature. Equipped with different die heads and auxiliary machines, our conical twin screw extruder can be devoted to the extrusion molding process of various tubing, boards, profiles, as well as soft and rigid PVC granules, among others.

Detailed Parameters

| Model | SJSZ-45 | SJSZ-51 | SJSZ-65 | SJSZ-80 | SJSZ-92 | SJSZ-95 |

| Screw Diameter (mm) | 45/90 | 51/105 | 65/132 | 80/156 | 92/188 | 95/191 |

| Average Length to Diameter Ratio (L/D) | 14.5 | 14.5 | 14.6 | 15.25 | 17.86 | 20.1 |

| Rotational Speed of Screw (r/min) | 3-34 | 3-37 | 3.9-39 | 3.9-39 | 3.5-35 | 4-40 |

| Main Motor Power (kW) | 15 | 22 | 37 | 67 | 110 | 132 |

| Barrel Heating Power (kW) | 15 | 16 | 28 | 38 | 65 | 85 |

| Output (kg/h) | 100 | 120 | 280 | 400 | 750 | 1200 |

| Center Height (mm) | 1000 | 1000 | 1000 | 1000 | 1150 | 1150 |

| Weight (kg) | 3000 | 3200 | 4000 | 5000 | 7000 | 9000 |

Related Names

Double Screw Extruding Machine Supplier | Plastic Handrail Production | Plastics Extrusion Machinery

Links:https://globefindpro.com/products/84016.html

-

SBG500 UPVC Double Wall Corrugated Pipe Extrusion Line

SBG500 UPVC Double Wall Corrugated Pipe Extrusion Line

-

PE Communication Pipe

PE Communication Pipe

-

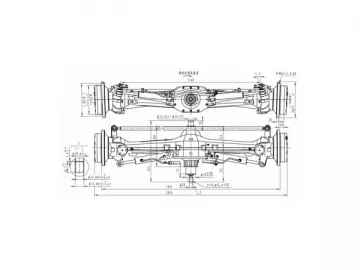

WZD75 Loader-Digger Drive Axle

WZD75 Loader-Digger Drive Axle

-

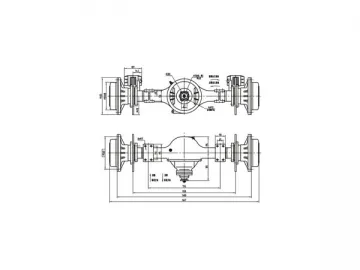

Wet Brake Drive Axle

Wet Brake Drive Axle

-

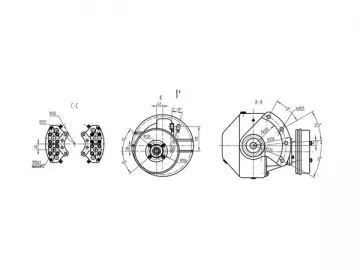

Caliper Disc Brake

Caliper Disc Brake

-

7T Forklift Truck Axle

7T Forklift Truck Axle

-

1.0-2.0T Drive Axle

1.0-2.0T Drive Axle

-

Ф300-Ф3000mm HDPE Steel Band Reinforced Spiral Pipe

Ф300-Ф3000mm HDPE Steel Band Reinforced Spiral Pipe

-

120 Horsepower Four-wheel Drive Tractor Axles

120 Horsepower Four-wheel Drive Tractor Axles

-

Construction Machinery Rim

Construction Machinery Rim

-

Single Screw Extruder

Single Screw Extruder

-

Insulated Water Supply Corrugated Pipe Extrusion Line

Insulated Water Supply Corrugated Pipe Extrusion Line