SBG500 UPVC Double Wall Corrugated Pipe Extrusion Line

Our SBG500 UPVC double wall corrugated pipe extrusion line is designed and developed by our company to satisfy the demand of plastic market. By absorbing the progressive technology from foreign competitors, we get the latest research achievement in the plastic extrusion molding field. Outside diameter of available pipe ranges from 160mm to 500mm.

This whole production line adopts the PVC high efficiency conical twin-screw extruder direct-molding process. It also comes with the professional PLC human-computer interface control system from Germany Siemens Company, featuring reliable quality, stable operation, as well as high degree of automation.

Main Specifications

| Components | Model | Overall Dimension (Length ×Width × Height) mm | Total Power(kW) | Weight(kg) |

| Extruder | SJSZ92 | 6000×1400×2390 | 200 (max.) | 8500 |

| MouldBlocks(Outside Diameter) | SBZG160 | 2000×Φ370 | 50 (max.) | 2000 |

| SBZG200 | 2400×Φ465 | 2600 | ||

| SBZG250 | 2800 | |||

| SBZG315 | 3000 | |||

| SBZG400 | 2400×Φ620 | 3500 | ||

| SBZG500 | 2400×Φ700 | 4000 | ||

| Corrugator | SBCJ500 | 4600×2120×2180 | 50 (max.) | 10000 |

| Cutter | QG6030 | 4252×2100×2400 | 7.5 | 3600 |

| Belling Machine | SGK500 | 8725×2600×2100 | 28 | 6000 |

Moreover, our UPVC double wall corrugated pipe extrusion line is equipped with the superior quality alloy-steel composite extrusion head processed by chrome-plating and polishing treatment. The corrugator adopts horizontal structure, and chain transmission. It is also provided with forced air cooling system and the advanced self-lubricating system.

The operation of aluminum alloy mould block makes use of the mechanical type up/down synchronous drive, which can ensure the quality stability of tubing. Controlled by the Siemens specialized PLC program, the cutting machine can be operated easily. All these advantages make this UPVC double wall corrugated pipe extrusion line popular among the customers from both home and abroad.

Sample

Related Names

High Strength Corrugated Piping Extruder | Modern Venting System | Pipe Production Solution

Links:https://globefindpro.com/products/84017.html

-

PE Communication Pipe

PE Communication Pipe

-

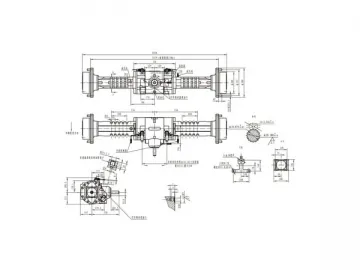

WZD75 Loader-Digger Drive Axle

WZD75 Loader-Digger Drive Axle

-

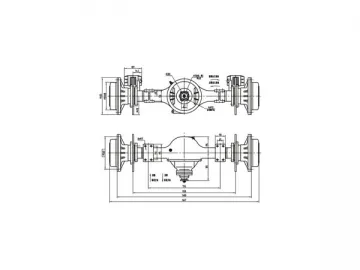

Wet Brake Drive Axle

Wet Brake Drive Axle

-

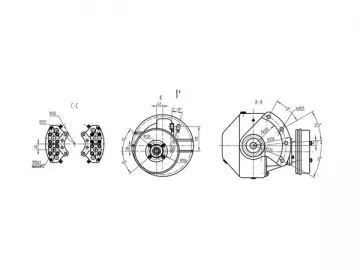

Caliper Disc Brake

Caliper Disc Brake

-

7T Forklift Truck Axle

7T Forklift Truck Axle

-

RT Base

RT Base

-

Conical Twin Screw Extruder

Conical Twin Screw Extruder

-

1.0-2.0T Drive Axle

1.0-2.0T Drive Axle

-

Ф300-Ф3000mm HDPE Steel Band Reinforced Spiral Pipe

Ф300-Ф3000mm HDPE Steel Band Reinforced Spiral Pipe

-

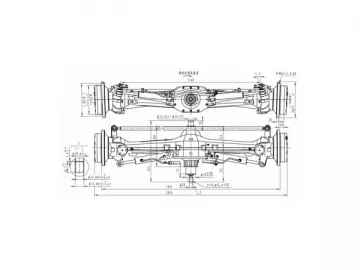

120 Horsepower Four-wheel Drive Tractor Axles

120 Horsepower Four-wheel Drive Tractor Axles

-

Construction Machinery Rim

Construction Machinery Rim

-

Single Screw Extruder

Single Screw Extruder