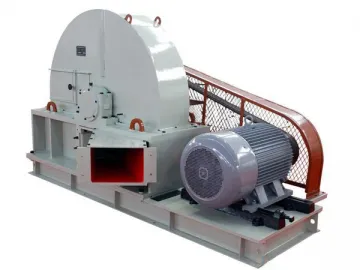

Rotary Drum Dryer

Working Principle

The rotation speed of the rotary drum dryer's main body can be regulated in a certain range. The wet materials are transported to the cylinder by the feeding device and are uniformly distributed within the drying machine via the stirring of the shoveling plate. They are in full contact with the hot air within the cylinder, accelerating heat transmission and mass transfer. Thus, the materials are dried up. This drying equipment can be fitted with various shoveling plates to process different materials. It boasts the simple structure, reliable running, convenient maintenance as well as great yield.

| Model | Diameter (mm) | Length (m) | Power (kW) | Speed of Rotation (RPM) |

| HZG6 | 600 | 4,5,6,7,8 | 3-5.5 | 3-20 adjustable |

| HZG8 | 800 | 4,5,6,7,8,9,10 | 5.5-7.5 | |

| HZG10 | 1000 | 6,7,8,9,10,11,12 | 5.5-7.5 | |

| HZG12 | 1200 | 6,8,10,12,14,16 | 7.5-11 | |

| HZG15 | 1500 | 8,10,12,14,16,18 | 11-15 | |

| HZG18 | 1800 | 8,10,12,14,16,18,20 | 15-18.5 | |

| HZG22 | 2200 | 10,12,14,16,18,20, 22,25 | 18.5-22 | |

| HZG24 | 2400 | 12,14,16,18,20,22,25 | 22-30 |

Technical Specifications (Part Two)

| Item (m) | Capacity (t/h) | Rotation Speed (RPM) | Motor Power (kW) | Angle (degree) | Temperature of Final Product |

| f1.0×5.0 | 0.5-1.2 | 0.6-6 | 4 | 3-5 | =1.5% |

| f1.2×6-10 | 1.5-3 | 0.6-6 | 5.5 | 3-5 | =1.5% |

| f1.5×12-18 | 3-5.5 | 0.6-6 | 15 | 3-5 | =1.5% |

| f1.8×12-18 | 5-6.5 | 0.6-6 | 18.5 | 3-5 | =1.5% |

| f2.2×12-22 | 7-12 | 0.6-6 | 22 | 3-5 | =1.5% |

| f2.4×15-20 | 9-15 | 0.6-6 | 30 | 3-5 | =1.5% |

| f3.0×25 | 16 | 0.6-6 | 55 | 3-5 | =1.5% |

The three layer rotary drum dryer is a new model of directly heated revolving cylinder drying machine. In comparison with traditional type, it is capable of saving energy consumption by one third with equal production. For this reason, this product has been popular among customers. Given the materials to be dried, it can be supplied with different heat resources, including directly or indirectly heated air furnace, heat conduction oil, electricity, etc.

This rotary drum dryer can be used to dewater a wide range of mash and residues, like brewery mash, alcohol mash, fruit residue, dregs of a decoction, tea residue, residue of soya, saccharified residue, fecula residue, straw, corncob, tree leaves, cocoanut shell, sawdust, wooden meal, wood shavings, etc. It has been extensively applied in bio-fuel, food, feed, chemical, mine and fertilizer making industries.

KMEC is an experienced rotary drum dryer manufacturer and supplier in China. Our company provides a wide range of products, including maize milling machine plant, oil bleaching equipment, electric pellet press machine, and more.

Related Names

Roll Dryer | Rotary Drying System

Links:https://globefindpro.com/products/82864.html