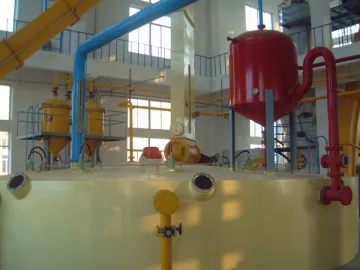

Oil Neutralization/Deacidification Process

The oil deacidification process aims to remove free fatty acid in oil. It mainly includes alkali refining type and steam distillation type which can be described as follows.

Alkali Refining Type

The alkali refining neutralization process can be used for deacidification, degumming, removal of solid impurities, decoloring, etc. It has strong applicability to crude oil. The saponification of neutral oil and the soap stock containing oil will result in high refining loss and great alkali consumption. After the alkali refining treatment, the oil will be washed with the water, producing waste water.

1. Continuous Alkali Refining Technique

With reference to American long-time, European medium-time and Alfa Laval Company's multiple mixing alkali refining technologies, our company develops the oil neutralization process suitable for oil having different kinds, qualities and processing requirements.

The alkali, water, acid and other things are added to the oil to remove free fatty acid, coarse phospholipids and moisture as much as possible. The product of such an alkali refining technique contains degummed neutral oil and by-products including soap stock, coarse phospholipids and water.

Advantages

a. The continuous alkali refining technique for neutralization process comes with good flexibility. It and the return passage can be flexibly adjusted in accordance with the specific conditions of oil products and requirements for refining degrees. In other words, this technique has better adaptability to different oil materials.

b. With the help of the imported centrifuge as well as appropriate operation, it is capable of minimizing the oil loss.

c. After being washed with water and dried up, the oil product can satisfy any requirements for subsequent deep processing.

2. Intermittent Alkali Refining Technique

a. Alkali Liquor → ①

b. Soft Water → ②

c. Crude Oil Filtering→ Pre-treatment→ Neutralization ① → Statically Standing for Sedimentation ③→ Deacidified Oil Containing Soap ②→ Water Washing→ Statically Standing for Sedimentation → Deacidified Oil Containing Water → Drying (Desolventizing) → Filtering→ Deacidified Oil

d. ③→Soapstock of Fat Oil→ Soapstock Processing→ Recovered Oil →Crude Oil Filtering

Deacidification with Distillation Method

This deacidification method is also called physical refining method which not uses the alkali liquor to neutralize the acid. It carries out the steam distillation at high temperatures and in high volume to remove free fatty acid and low molecular substances, in line with different relative volatility of triglyceride and free fatty acid. This method is suitable for high acid value oil.

Since the colloid and mechanical impurities are hard to remove by the high temperature distillation, the oil has to be filtered and degummed prior to distillation deacidification. The crude oil with high acid value can be processed by combining both steam distillation method with alkali refining methods.

Advantages

1. Adopting distillation method to remove acid, the equipment for deacidification process reduces the loss of neutral oil

2. It consumes fewer auxiliary materials, thus decreasing the pollution of waste water to environment.

3. This technique is characterized by simplicity, less equipment but high refining rate.

4. It also has deodoration function, making good the flavor of the finished oil.

5. The distillation deacidification method is especially excellent for low-colloid oil, such as coconut oil, palm oil, adipose, etc.

KMEC is a specialized oil neutralization/deacidification equipment manufacturer and supplier in China. We offer a broad range of products, including wood debarker, electric pellet press machine, wheat scourers and wheat brushing machine, rotary grading sieve, and more.

Related Names

Neutralization Solution | Alkali Refining Process

Links:https://globefindpro.com/products/82870.html