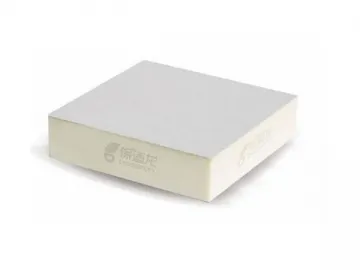

Rigid PU Foam Insulation for Refrigerator and Freezer

The rigid PU foam insulation which is widely applied to refrigerators and freezers, is comprised of system polyol and isocyanate. The formula of system polyol covers polyether polyol, silicone surfactant, catalyst, and additives. Such three foaming systems as HCFC-141B, cyclopentane, and HFC-245fa based type, are for selection.

Properties

This rigid PU foam system comes with the characteristics including short stripping time as well as excellent stability, operability, and mobility. After added with foaming agent, the system polyol will react with isocyanate to form PU foam insulation material characterized by uniform density, high strength, and excellent dimensional stability. This insulation material has strong viscosity. Its performances reach the international advanced level.

In addition, the cyclopentane or HFC-245fa based PU foam insulation is defined as the environmental materials, since it has no damage to the ozone sphere.

LC-1001H Rigid PU Foam Insulation for Refrigerator and Freezer

Technical Property

| Product | LC-1001H | ||

| Manual | Machine | ||

| Blowing agent | type | HFC-245fa | |

| Mixing ratio | (pol/iso) | 100/117~120 | |

| Cream time | Sec. | 10~13 | 9~12 |

| Gel time | Sec. | 80~85 | 65~75 |

| Track free time | Sec. | 100~130 | 90~120 |

| Free rise density | kg/m³ | 24~25 | 23.5~25 |

| Molded density | kg/m³ | / | 38~42 |

Foam Property

| GB/T 26689-2011 Rigid polyurethane cellular plastics used in refrigerators and freezers type I is cyclopentane blown, type II is other blowing agent | |||||

| I | II | ||||

| Thermal conductivity (Average temperature 10ºC) | ≤ | W/m.k | 0.021 | 0.0196 | |

| Compressive strength (10% deformation) | ≥ | MPa | 130 | 110 | |

| Dimensional stability ( -30ºC×24h) (70ºC, RH 95±5%×24h) | ≤ | % | 1 | ||

| 1.5 | |||||

| Apparent core density | ≤ | kg/m³ | 38 | 35 | |

| Closed cell rate | ≥ | % | 90 | ||

| water absorption: | ≤ | % | 3 | ||

LC-1001H Rigid PU Foam Insulation for Refrigerator and Freezer

LC-1024W Rigid PU Foam Insulation for Refrigerator and Freezer

Technical Property

| Product | LC-1024W | ||

| Manual | Machine | ||

| Blowing agent | type | Cyclopentane | |

| Mixing ratio | (pol/cp/iso) | 100/12~13/135~142 | |

| Cream time | Sec. | 10~13 | 9~12 |

| Gel time | Sec. | 80~85 | 65~75 |

| Track free time | Sec. | 100~130 | 90~120 |

| Free rise density | kg/m³ | 24~25.5 | 23.5~25.5 |

| Molded density | kg/m³ | / | 35~42 |

Foam Property

| GB/T 26689-2011 Rigid polyurethane cellular plastics used in refrigerators and freezers type I is cyclopentane blown, type II is other blowing agent | |||||

| I | II | ||||

| Thermal conductivity (Average temperature 10ºC) | ≤ | W/m.k | 0.021 | 0.0196 | |

| Compressive strength (10% deformation) | ≥ | MPa | 130 | 110 | |

| Dimensional stability ( -30ºC×24h) (70ºC, RH 95±5%×24h) | ≤ | % | 1 | ||

| 1.5 | |||||

| Apparent core density | ≤ | kg/m³ | 38 | 35 | |

| Closed cell rate | ≥ | % | 90 | ||

| Water absorption | ≤ | % | 3 | ||

LC-1025H Rigid PU Foam Insulation for Refrigerator and Freezer

Technical Property

| Product | LC-1025H | ||

| Manual | Machine | ||

| Blowing agent | type | HCFC-141b | |

| Mixing ratio | (pol/iso) | 100/100~110 | |

| Cream time | Sec. | 10~15 | 8~14 |

| Gel time | Sec. | 75~85 | 60~75 |

| Track free time | Sec. | 100~140 | 90~125 |

| Free rise density | kg/m³ | 24~25 | 23.5~25 |

| Molded density | kg/m³ | / | 35~40 |

Foam Property

| GB/T 26689-2011 Rigid polyurethane cellular plastics used in refrigerators and freezers type I is cyclopentane blown, type II is other blowing agent | |||||

| I | II | ||||

| Thermal conductivity (Average temperature 10ºC) | ≤ | W/m.k | 0.021 | 0.0196 | |

| Compressive strength (10% deformation) | ≥ | MPa | 130 | 110 | |

| Dimensional stability ( -30ºC×24h) (70ºC, RH 95±5%×24h) | ≤ | % | 1 | ||

| 1.5 | |||||

| Apparent core density | ≤ | kg/m³ | 38 | 35 | |

| Closed cell rate: | ≥ | % | 90 | ||

| Water absorption: | ≤ | % | 3 | ||

LC-1025H Rigid PU Foam Insulation for Refrigerator and Freezer

Related Names

Polyurethane Prepolymer | Rigid Foam Insulation Panel | High Density Foam Sheet

Links:https://globefindpro.com/products/85078.html

-

Rigid PU Spray Foam Insulation

Rigid PU Spray Foam Insulation

-

Perkins Diesel Generator Set

Perkins Diesel Generator Set

-

Color-Coated Steel PU Insulated Sandwich Panel

Color-Coated Steel PU Insulated Sandwich Panel

-

Cummins Diesel Generator Set

Cummins Diesel Generator Set

-

Electric Chain Hoist

Electric Chain Hoist

-

Explosion-Proof Crane

Explosion-Proof Crane

-

Push and Geared Trolley

Push and Geared Trolley

-

Diesel and Gas Generator Set

Diesel and Gas Generator Set

-

LC-5000 Rigid PU Foam for Packaging

LC-5000 Rigid PU Foam for Packaging

-

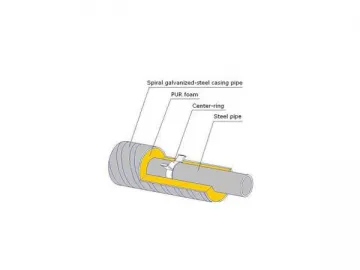

Rigid PU Foam Pipe Insulation

Rigid PU Foam Pipe Insulation

-

Fiberglass Reinforced PU Insulated Sandwich Panel

Fiberglass Reinforced PU Insulated Sandwich Panel

-

Deutz Diesel Generator Set

Deutz Diesel Generator Set