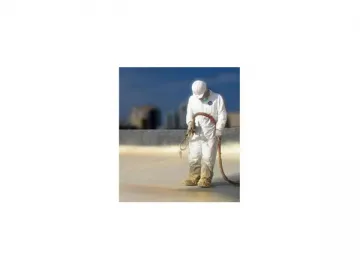

Rigid PU Spray Foam Insulation

The rigid PU spray foam designed for insulation purpose, comprises system polyol and isocyanate. System polyol is fully formulated of polyol, fire retardant, silicone surfactant, catalysts, and additives. This PU spay foam system is developed to make rigid foam with closed cells. It is blown with CFC free. HCFC-141B or HFC-245fa based foaming systems are available.

Properties

1. Viscosity

This rigid PU spray foam insulation has a strong bonding capacity. It adheres to a variety of substrates such as concrete, block, wood, steel, asphalt, rubber, etc.

2. Heat Conductivity Coefficient

This system has the heat conductivity coefficient ranging from 0.017 W/m.k to 0.022W/m.k, which is lower than that of the building insulation materials, for instance, rock wool, glass wool, polystyrene board, extruded plate, etc.

3. Hydrophobic Property

The hydrophobicity is at least 95%.

4. Sealing Property

Our product offers good air-tightness. It can thoroughly wrap the building envelope without any cavity or seam.

5. Dimensional Stability

The dimensional stability is smaller than 1%. Our rigid PU spray foam insulation is flexible with the elongation above 5%.

6. Stable Performance

It is known that polyurethane is a inert material which will not react with acid or base. It is mothproof.

7. Wind-resistant Performance

With the compressive strength above 300Kpa and the tensile strength greater than 400Kpa, this type of rigid PU foam perfectly resists wind. It can get into the wall cracks to increase the shear performance.

8. Good Fire Resistance

The rigid PU spray foam insulation has been carbonized, so it resists fire and will not generate molten drop. It has smaller relative density, but comes with high intensity and good shockproof performance.

9. Freely Adjustable Application Method and Formula

Our product can be adjusted according to different applications. Both spraying and pouring methods are available.

LC-6023 Rigid PU Spray Foam Insulation

Product Property| Product | LC-6023 | ||

| Manual | Machine | ||

| Blowing agent | type | HCFC-141b | |

| Mixing ratio | (pol/iso) | 100/100 | |

| Cream time | Sec. | 3~6 | 2~4 |

| Gel time | Sec. | / | / |

| Track free time | Sec. | 10~15 | 6~10 |

| Free rise density | kg/m3 | ≥22 | ≥21 |

| Sprayed density | kg/m3 | / | ≥35 |

| JC/T998-2006 NEQ DIN18159-1991 PART 1 Spray polyurethane foam for thermal insulation I is for wall, II-A is for roof not withstand people, II-B is for roof withstand people | ||||

| Items | Parameter | |||

| I | II-A | II-B | ||

| Density (kg/m3) | ≥ | 30 | 35 | 50 |

| Thermal conductivity (W/m.k) (Average temperature 23ºC) | ≤ | 0.024 | ||

| Adhesive strength (kPa) | ≥ | 100 | ||

| Dimensional stability (70ºC×48h) % | ≤ | 1 | ||

| Compressive strength (kPa) | ≥ | 150 | 200 | 300 |

| Tensile strength (kPa) | ≥ | 10 | ||

| Closed-cell rate (%) | ≥ | 92 | 95 | |

| Water absorption (%) | ≤ | 3 | ||

| Moisture vapor transmission (ng/Pa.m.s) | ≤ | 5 | ||

| Impermeability (mm) (1000mm water cylinder×24h hydrostatic pressure) | ≤ | 5 | ||

LC-6024 Rigid PU Spray Foam Insulation

Product Property| Product | LC-6024 | ||

| Manual | Machine | ||

| Blowing agent | type | HCFC-141b | |

| Mixing ratio | (pol/iso) | 100/100 | |

| Cream time | Sec. | 3~6 | 2~4 |

| Gel time | Sec. | / | / |

| Track free time | Sec. | 10~15 | 6~10 |

| Free rise density | kg/m3 | ≥22 | ≥21 |

| Sprayed density | kg/m3 | / | ≥35 |

| JC/T998-2006 NEQ DIN18159-1991 PART 1, spray polyurethane foam for thermal insulation, I is for wall, II-A is for roof not withstand people, II-B is for roof withstand people | ||||

| Items | Parameter | |||

| I | II-A | II-B | ||

| Density (kg/m3) | ≥ | 30 | 35 | 50 |

| Thermal conductivity (W/m.k) (Average temperature 23ºC) | ≤ | 0.024 | ||

| Adhesive strength (kPa) | ≥ | 100 | ||

| Dimensional stability (70ºC×48h) (%) | ≤ | 1 | ||

| Compressive strength (kPa) | ≥ | 150 | 200 | 300 |

| Tensile strength (kPa) | ≥ | 10 | ||

| Closed-cell rate (%) | ≥ | 92 | 92 | |

| Water absorption (%) | ≤ | 3 | ||

| Moisture vapor transmission (ng/Pa.m.s) | ≤ | 5 | ||

| Impermeability, mm (1000mm water cylinder×24h hydrostatic pressure ) | ≤ | 5 | ||

LC-6024HFC Rigid PU Spray Foam Insulation

Product Property| Products | LC-6024HFC | ||

| Manual | Machine | ||

| Blowing agent | type | HCFC-141b | |

| Mixing ratio | (pol/iso) | 100/100 | |

| Cream time | Sec. | 3~6 | 2~4 |

| Gel time | Sec. | / | / |

| Track free time | Sec. | 10~15 | 6~10 |

| Free rise density | kg/m3 | ≥22 | ≥21 |

| Sprayed density | kg/m3 | / | ≥35 |

| JC/T998-2006 NEQ DIN18159-1991 PART 1 Spray polyurethane foam for thermal insulation I is for wall, II-A is for roof not withstand people, II-B is for roof withstand people | ||||

| Items | Parameter | |||

| I | II-A | II-B | ||

| Density (kg/m3) | ≥ | 30 | 35 | 50 |

| Thermal conductivity (W/m.k) (Average temperature 23ºC) | ≤ | 0.024 | ||

| Adhesive strength (kPa) | ≥ | 100 | ||

| Dimensional stability (70ºC×48h) % | ≤ | 1 | ||

| Compressive strength (kPa) | ≥ | 150 | 200 | 300 |

| Tensile strength (kPa) | ≥ | 250 | - | - |

| Elongation at break (%) | ≥ | 10 | ||

| Closed-cell rate (%) | ≥ | 92 | 95 | |

| Water absorption (%) | ≤ | 3 | ||

| Moisture vapor transmission (ng/Pa.m.s) | ≤ | 5 | ||

| Impermeability (mm) (1000mm water cylinder×24h hydrostatic pressure ) | ≤ | 5 | ||

LC-6028 Rigid PU Spray Foam Insulation

Product Property| Product | LC-6028 | ||

| Manual | Machine | ||

| Blowing agent | type | HCFC-141b | |

| Mixing ratio | (pol/iso) | 100/100 | |

| Cream time | Sec. | 3~6 | 2~4 |

| Gel time | Sec. | / | / |

| Track free time | Sec. | 10~15 | 6~10 |

| Free rise density | kg/m3 | ≥22 | ≥21 |

| Sprayed density | kg/m3 | / | ≥35 |

| JC/T998-2006 NEQ DIN18159-1991 PART 1 Spray polyurethane foam for thermal insulation I is for wall, II-A is for roof not withstand people, II-B is for roof withstand people | ||||

| Items | parameter | |||

| I | II-A | II-B | ||

| Density (kg/m3) | ≥ | 30 | 35 | 50 |

| Thermal conductivity (W/m.k) (Average temperature 23ºC) | ≤ | 0.024 | ||

| Adhesive strength (kPa) | ≥ | 100 | ||

| Dimensional stability (70ºC×48h) % | ≤ | 1 | ||

| Compressive strength (kPa) | ≥ | 150 | 200 | 300 |

| Tensile strength (kPa) | ≥ | 250 | - | - |

| Elongation at break (%) | ≥ | 10 | ||

| Closed-cell rate (%) | ≥ | 92 | 95 | |

| Water absorption (%) | ≤ | 3 | ||

| Moisture vapor transmission (ng/Pa.m.s) | ≤ | 5 | ||

| Impermeability (mm) (1000mm water cylinder×24h hydrostatic pressure ) | ≤ | 5 | ||

LC-6095B2 Rigid PU Spray Foam Insulation

Product Property| Product | LC-6095B2 | ||

| Manual | Machine | ||

| Blowing agent | type | HCFC-141b | |

| Mixing ratio | (pol/iso) | 100/100 | |

| Cream time | Sec. | 3~6 | 2~4 |

| Gel time | Sec. | / | / |

| Track free time | Sec. | 10~15 | 6~10 |

| Free rise density | kg/m3 | ≥22 | ≥21 |

| Sprayed density | kg/m3 | / | ≥35 |

| JC/T998-2006 NEQ DIN18159-1991 PART 1 Spray polyurethane foam for thermal insulation I is for wall, II-A is for roof not withstand people, II-B is for roof withstand people | ||||

| Items | Parameter | |||

| I | II-A | II-B | ||

| Density (kg/m3) | ≥ | 30 | 35 | 50 |

| Thermal conductivity (W/m.k) (Average temperature 23ºC) | ≤ | 0.024 | ||

| Adhesive strength (kPa) | ≥ | 100 | ||

| Dimensional stability (70ºC×48h) % | ≤ | 1 | ||

| Compressive strength (kPa) | ≥ | 150 | 200 | 300 |

| Tensile strength (kPa) | ≥ | 250 | - | - |

| Elongation at break (%) | ≥ | 10 | ||

| Closed-cell rate (%) | ≥ | 92 | 92 | |

| Water absorption (%) | ≤ | 3 | ||

| Moisture vapor transmission (ng/Pa.m.s) | ≤ | 5 | ||

| Impermeability (mm) (1000mm water cylinder×24h hydrostatic pressure ) | ≤ | 5 | ||

Related Names

Closed Cell Spray Foam | Polyurethane Elastomer | Expanding Spray Foam Kit

Links:https://globefindpro.com/products/85079.html

-

Perkins Diesel Generator Set

Perkins Diesel Generator Set

-

Color-Coated Steel PU Insulated Sandwich Panel

Color-Coated Steel PU Insulated Sandwich Panel

-

Cummins Diesel Generator Set

Cummins Diesel Generator Set

-

Electric Chain Hoist

Electric Chain Hoist

-

Explosion-Proof Crane

Explosion-Proof Crane

-

Water Pump Diesel Engine

Water Pump Diesel Engine

-

Rigid PU Foam Insulation for Refrigerator and Freezer

Rigid PU Foam Insulation for Refrigerator and Freezer

-

Push and Geared Trolley

Push and Geared Trolley

-

Diesel and Gas Generator Set

Diesel and Gas Generator Set

-

LC-5000 Rigid PU Foam for Packaging

LC-5000 Rigid PU Foam for Packaging

-

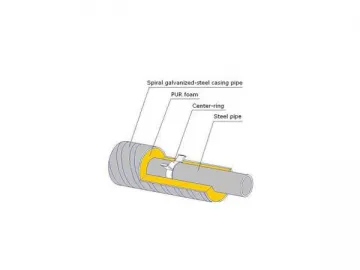

Rigid PU Foam Pipe Insulation

Rigid PU Foam Pipe Insulation

-

Fiberglass Reinforced PU Insulated Sandwich Panel

Fiberglass Reinforced PU Insulated Sandwich Panel