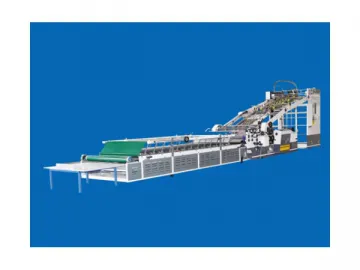

Automatic Folder Gluer

As a kind of commonly used carton making machine, an automatic folder gluer is typically made up of the feeding, gluing and folding units. For greater convenience, our range of carton folding and gluing machine is additionally designed with counting and stacking functions.

Paper Feeding Unit

1. The automatic carton folder gluer adopts the vacuum suction feeding mode to ensure smooth feeding of warping paperboards.

2. The feeding unit is independently controlled by a top performance electromagnetic clutch, thus making operation simple and dependable.

3. This range of paper box folder gluer uses an imported rubber belt for smooth and safe delivering of paperboards. With great wearing resistance, the rubber belt offers long service life.

Gluing and Folding Unit

1. The automatic carton folding and pasting machine employs stainless steel gluing rollers to ensure convenient cleaning, uniform glue coating, and reduced glue waste.

2. A simple but reliable electrical control unit is adopted to control the glue quantity, which further saves glue.

3. Paperboard position-correction device and creasing unit are available. With adjustable creasing wheels, the automatic folder gluer is applicable for cardboards with thickness between 2 and 8mm.

4. A secondary creasing mechanism is available to perform a second time creasing on the paperboards when the first time creasing quality is poor.

Counting and Stacking Unit

1. The counting and stacking unit works on the basis of a simple principle. It is digitally controlled to deliver reliable operation. Supporting non-stop data input, the unit offers efficiency and accurate output.

2. Position correction function is available.

3. Adopting pneumatic method for end product collection, the automatic folder gluer is provided with accurate and fast stacking.

Parameters

| Model | SR-2400 | SR-2800 |

| Maximum Size of Paperboard (mm) | 900 ×2200 | 1200 ×2600 |

| Minimum Size of Paperboard (mm) | 300 ×900 | 300 ×900 |

| Dimensions (mm) | L11000 ×W3000 ×H1600 | L12500 ×W3400 ×H1600 |

| Total Weight | 6000kg | 7000kg |

| Power Supply | 11.5KW 380V 3 phase 50Hz | 14.5KW 380V 3 phase 50Hz |

| Paperboard Thickness | 3 or 5 layers paperboard | |

| Control | PLC and Touch screen | |

Links:https://globefindpro.com/products/84851.html

-

XT-D Series Rotary Cutting and Creasing Machine

XT-D Series Rotary Cutting and Creasing Machine

-

XT-L Series 2-Color Flexo Printer Slotter

XT-L Series 2-Color Flexo Printer Slotter

-

Taper Shank Drill Bit

Taper Shank Drill Bit

-

XT-M Series Rotary Die Cutting Machine

XT-M Series Rotary Die Cutting Machine

-

Automatic Strapping Machine

Automatic Strapping Machine

-

Multifunction Automatic Folder Gluer

Multifunction Automatic Folder Gluer

-

XT-G Series Rotary Die Cutting Machine

XT-G Series Rotary Die Cutting Machine

-

Semi-Auto Box Stitching Machine

Semi-Auto Box Stitching Machine

-

Automatic Partition Slotting Machine

Automatic Partition Slotting Machine

-

Automatic Flatbed Die Cutting Machine

Automatic Flatbed Die Cutting Machine

-

Combined Rotary Creasing Slotting and Slitting Machine

Combined Rotary Creasing Slotting and Slitting Machine

-

Automatic Laminating Machine

Automatic Laminating Machine