DSM Plastic Mill

Description

DSM plastic mill is a disc-type automatic plastic milling machine. In the ambient temperature, it is ideally suited to smash thermoplastics, for instance, PE, LDPE, PET, PVC, SBS, PC, PS, and so on. Our milling machine holds the advantages of low power consumption, convenient operation, etc. It can smash the materials with superfine granularity.

Working Principle

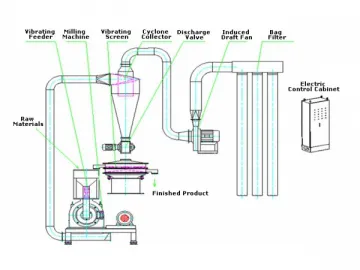

With the vibrating feeding machine, the material will be quantitatively fed to the milling machine. In the smashing area made up of moving millstone and static millstone, the material will be unremittingly smashed from inside to outside. After coarsely crushed in the inner smashing area, it will be then grinded into the desired micro power in the outer smashing area. Finally, the powder will be uniformly discharged via the centrifuge.

The processed micro powder, under the effect of the high-pressure centrifugal fan, will be connected by the cyclone collector. Then, through the discharge valve, the powder will get into the vibrating sieving machine, so as to separate the fine power and coarse powder. The fine power will be expelled out, while the coarse powder will get back to the milling machine for continuous smashing.

Technical Features

1. With the vibrating feeder, the materials can be evenly fed. Thus, either the fineness or device stability can be ensured.

2. Our milling machine is easy to operate. The interval between the moving disc and fixed disc can be conveniently adjusted.

3. Made of alloy steel, the millstone is reusable.

4. Based on the material characters, the mill is available with several cooling methods, such as cooling by wind, water, air cooler, or others.

5. According to the fineness requirement and the material properties, the DSM plastic mill is designed with the single or double millstones as well as single-side or double-side fluted disc.

Parameters

| Model | Rotor Diameter (mm) | Matched Power (kw) | Rotational Speed (r/min) | Maxi. Processing Air Volume (m3/h) | Fineness of Pulverization (um) | Output (kg/h) |

| DSM-380 | 380 | 22 | 7550 | 1600 | 5~250 | 30~200 |

| DSM-550 | 500 | 45 | 4700 | 2400 | 5~250 | 80~2000 |

| DSM-750 | 700 | 75 | 3000 | 3600 | 5~250 | 100~3000 |

Remark: The output is related to the material property, and fineness. The above information is for reference only.

Application

The DSM plastic milling machine is suitable for thermoplastic PE powder, power for rotational moulding, XLPE cable colloidal particles, as well as powder for plastic dipping and spraying. Also, it can smash engineering plastic, hard PVC waste, and so forth.

As an experienced plastic mill manufacturer and supplier in China, It provides a comprehensive range of products, including spiral flow jet mill, turbo rotor mill, powder mixing, drying and granulating equipment, rotor classifier, and more.

Related Names

Plastic Grinder | Plastic Grinding Machine | Plastic Pulverizer

Links:https://globefindpro.com/products/84943.html

-

Skeletal Container Semi-trailer

Skeletal Container Semi-trailer

-

HS36 Radial Ply Tire

HS36 Radial Ply Tire

-

Oil Tank Semi-trailer

Oil Tank Semi-trailer

-

Rustic Floor Tile

Rustic Floor Tile

-

High Dropside Cargo Semi-trailer

High Dropside Cargo Semi-trailer

-

FW Superfine Powder Classifier

FW Superfine Powder Classifier

-

22.5×13.00 Tubeless Wheel

22.5×13.00 Tubeless Wheel

-

Low Bed Semi-trailer

Low Bed Semi-trailer

-

HS26 Radial Ply Tire

HS26 Radial Ply Tire

-

NLM Ultra-Low Temperature Pulverizer

NLM Ultra-Low Temperature Pulverizer

-

22.5×9.00 Tubeless Wheel

22.5×9.00 Tubeless Wheel

-

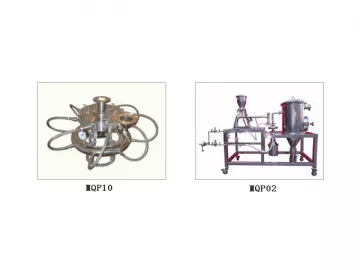

MQP Disc Jet Mill

MQP Disc Jet Mill