FW Superfine Powder Classifier

Description

The FW superfine powder classifier applies the technologies from China and Germany. It is a superfine powder grading equipment ideal for low to medium hardness micro powder. Its performance index reaches the international standard. Equipped with a high accurate turbine, this machine can be applicable for the finest materials with the fineness of 2μm. The rotor made of special material can classify the materials of high hardness. Consequently, the classifier is ideal for the gradation, iron removal, and selection, in the industries including chemical industry, medicine, food, non-metallic mines, etc.

Working Principle

Due to the feeding machine, the material will be sucked into the grading chamber by the high-pressure vacuum suction system. Between the turbine and turbine housing where the strong centrifugal force field exists, the powder will be graded. The expected fine powder will be collected by the gathering unit. In addition, the coarse powder will get into the lower cabinet for re-grading. Through this way, the fine power mixed in the coarse powder will again get into the grading chamber along with the airflow. The coarse waste will fall along with the inner wall, and be collected via the discharge device. Both the turbine and the upper cabinet apply the sealing structure, which allows excellent sealing effect. Consequently, the uniform discharging granularity is ensured. By adjusting the rotating speed of the driving motor and the secondary air flow supply amount, you can obtain the optimal classification effect.

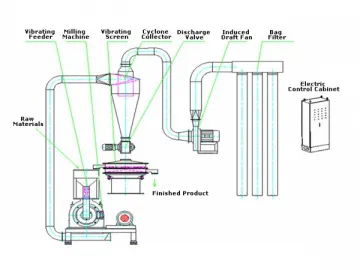

Working Principle Diagram

Features

1. The FW superfine powder classifier is appropriate for the dry grading of micro powder. It can classify the globular powder, flaky powder, and acicular powder. Also, it is suitable for classifying the particles of different densities.

2. The powder after classified comes with the fineness of D97: 2 to 45μm. The product fineness can be stepless adjusted.

3. Generally, the classification efficiency ranges from 60% to 80%. The better the material mobility is, the higher the grading efficiency will be.

4. With the horizontal type turbine device, this classifier features high rotating speed and accurate vertex cutting.

5. Our machine can be connected with the ball mill, vibromill, raymond mill, etc. to form the closed cycle.

6. The controlling system adopts the PLC automatic control to offer the user-friendly control and realize the real-time display of the operating status.

7. This classifier offers the dust discharge amount no more than 40mg/m3. The adoption of the sound-insulation method allows the noise less than 75dB (A).

| Item/Model | FW400/3D | FW400/4D | FW400/6D | FW630/3D | FW630/4D | FW630/6D | FW800/3D | FW800/4D | FW800/6D |

| Handling Capacity T/h | 0.2~1.5 | 0.3~2 | 0.5~3 | 1~5 | 2~8 | 3~10 | 2~8 | 3~10 | 5~15 |

| Product Fineness d97:um | 2~45 | 2~45 | 2~45 | 3~45 | 3~45 | 3~45 | 4~454 | ~45 | 4~45 |

| Grading Efficiency % | 60~80 | 60~80 | 60~80 | 60~80 | 60~80 | 60~80 | 60~80 | 60~80 | 60~80 |

| Installed Power (kw) | 90-110 | 120-140 | 170-200 | 135-155 | 170-190 | 250-290 | 180-200 | 220-290 | 290-390 |

Parameter of FW series

| Item /Model | FW200 | FW280 | FW400 | FW520 | FW630 | FW800 |

| Handling Capacity T/h | 10~100 | 20~200 | 50~500 | 100~1500 | 200~2000 | 400~4000 |

| Product Fineness d97:um | 2~45 | 2~45 | 2~45 | 3~45 | 3~45 | 4~45 |

| Grading Efficiency (%) | 60~80 | 60~80 | 60~80 | 60~80 | 60~80 | 60~80 |

| Installed Power (kw) | 7-11 | 15-19 | 21-28 | 23-30 | 52-60 | 67-77 |

Application Case

1. Industrial minerals, calcium carbonate, kaolin, quartz, talc, mica, graphite

2. Powder metallurgy abrasive, ceramic refractory material

3. Medicine, pesticide, food, health care products, carbon material, or other new materials

It is a professional superfine powder classifier manufacturer and supplier in China. We provide a variety of products, including rotor classifier / powder grader, vacuum conveyor, ultra-low temperature pulverizer, and more.

Related Names

High Accuracy Powder Classification | Classifying Equipment in Food Industry | Non-metal Classification

Links:https://globefindpro.com/products/84949.html