NLM Ultra-Low Temperature Pulverizer

Description

In the NLM series ultra-low temperature fine milling process, the particle or lump material will be made to the suitable power through the mechanical force or high-speed airflow. During such process, the smashing method may not work due to the materials physical property. Especially when it comes to the ultrafine grinding of heat sensitive material, the power made with the low-temperature processing has been widely applied in all the sectors. For instance, we smash the hot-melt adhesive into the type with low melting point, strong adhesive force, and good permeability. As a result of the low melting and softening point, this kind of material must be smashed in the low temperature rather than the room temperature. Our machine also can be used for the plastic laser sintering materials, military absorbing materials, medical industry, anticorrosion industrial coatings, etc.

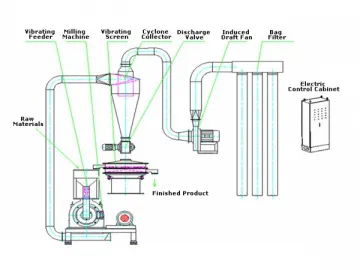

| 1. Raw Material2. Exhaust3. screw conveyor4. Hopper5. Induced Draft Fan6. Collector7. Discharging Valve8. Finish Product9. Grinder10. Liquid Nitrogen |

Parameter

| Model | 250 | 400 | 600 |

| Motor Power(KW) | 30KW | 60KW | 100KW |

| Maxi. Rotate Speed of Main Axle(r/min) | 7500 | 4650 | 3200 |

| Finished Product Fineness | 80~1200 mesh | ||

Application

Chemical and Coating Field: Teflon, PU, PP, Nylon PA, Potassium Permanganate.

Food and Health Care Products: Plant fruit, Animal and Plant Extracts, Ground Pepper, Ground Cinnamon, Cumin Powder, Paprika Powder, Curry Powder, Aniseed Powder, etc.

Biotechnology Industry: Conidial Powder, Protein, Vitamin, Animal Placenta, Plant Andvegetable Extracts.

It is a professional ultra-low temperature pulverizer manufacturer and supplier in China. We offer a comprehensive range of products, including rubber pulverizer, fluidized bed jet mill, large capacity powder grading machine, and more.

Related Names

Pharmaceutical Grinding Mill | Food Pulverizer | Grinder in Biotechnology

Links:https://globefindpro.com/products/84939.html